-

The Sentry W9000 Series sample coolers are designed for small volume hot water samples. The efficient counterflow design provides cooling for samples up to 750°F (399°C) and 3500 psig (241.3 barg), and the simplicity provides maximum cooling at minimal cost. With a compact design, simple installation and high quality materials, the W9000 Series sample coolers are the best low capacity option for small volume hot water samplers of water or other liquids.

-

The Sentry high-temperature shut-off valve is designed for use with sampling systems to shut off flow when the sample temperature becomes too hot. The valve is suitable for grab sample or instrument applications that could experience a loss of coolant or surges in sample flow rates, which would cause the sample temperture to rise suddenly.

-

The Extrel Atmospheric Pressure Ionization Mass Spectrometer (APIMS) was designed to have reliable and repeatable low parts per trillion detection limits for gas contaminates. The VeraSpec™ Trace system has been the first choice for ultra high purity (UHP) gas contamination analysis and trace pollution studies for over twenty-five years.

-

Suited to steam-regulated heat exchangers, vacuum systems, drying cylinders, steam dryers and systems with very low operating or differential pressures, GESTRA's ball float steam traps remove condensate from steam, cold condensate, and distillates.

-

The Sentry TSV is a self-contained, mechanical device that protects operators, analyzers and sampling components from high temperature liquids. It is an economical and reliable mechanical replacement for a solenoid shutoff valve and temperature controller, requiring no external source of electricity, air or hydraulics.

-

The Sentry TRW sample cooler cools a sample from a process stream. It may seem simple, but it is a uniquely designed small tube in a shell heat exchanger. The sample to be cooled flows through the tube side of the cooler, and the cooling fluid, usually water, flows through the shell side. The cooled sample then is taken to a laboratory for analysis or piped to in-line process instrumentation for continuous monitoring of properties such as conductivity, pH or other chemical constituents

-

Benchmark Measurement Solutions, formerly Turner Designs Hydrocarbon Instruments, proudly announces the all new dual-channel TD-560 Oil in Water Analyzer. In addition to the optical channel found in the TD-550, suitable for crude and other heavy oils, the TD-560 adds a second channel for detecting lighter hydrocarbons, such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol. The TD-560 offers a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers.

-

Benchmark Measurement Solutions, formerly Turner Designs Hydrocarbon Instruments, is proud to introduce the new standard in grab sample oil in water analysis with the TD-550 oil in water analyzer. The TD-550 is suitable for crude oils and other heavy oils with a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers. Related product, the TD-560, includes the same optical channel of the TD-550 along with a second optical channel for detecting lighter hydrocarbons such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol.

-

The TD-4100XDC General Purpose oil in water monitor is a lower cost version of the industry standard TD-4100XDC and is designed for use in non-explosive atmospheres. It was designed for normally clean water applications, or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems.

-

The TD-4100XDC is a closed cell version of the rugged, world industry standard TD-4100XD Oil in Water Monitor. It was designed for normally clean water applications or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It utilizes a clear tube flow cell to contain the sample water at pressure to prevent oxygen contamination in steam systems and to return the sample to the process at pressure. It uses a unique internal cell condition monitor to alert operations of the need for cleaning or to trigger the optional onboard cleaning system. As with all Benchmark Measurement Solutions monitors, it includes a field validation method.

-

The TD-4100XD General Purpose monitor is a lower cost version of the industry standard TD-4100XD and is designed for use in non-explosive atmospheres. It was designed for dirty water applications and uses our standard EZ Access noncontact flow cell for lower maintenance. Field validation is via our CheckPOINT™ solid calibration check standard.

-

The TD-4100XD is a ruggedized version of the TD-4100 continuous online oil in water monitor. The XD is designed specifically for offshore oil production, refining, petrochemical, mining, and other industries that require robust online hardware for severe duty and hazardous area locations. The monitor is skid or wall mounted and constructed of 316 stainless steel.

-

The TD-2500 combines ultrasonics and a time-tested insertion probe to offer the ultimate in early detection of high concentrations, or slugs, of oil in waste water. Ultrasonic technology measures oil at high concentrations, typically seen after oil/water separation, is sensitive to droplets, solids or gas bubbles and is easier to maintain than optical technologies.

-

The TD-120 Oil in Water Monitor is ideal for detection of oil leaks from heat exchangers—protecting boilers, water intakes and membrane systems—as well as optimizing water treatment systems. With low detection limits and extended measurement range, the TD-120 provides the necessary tools and ease of use to meet today’s complex oil in water measurement needs.

-

The SulfiLoggerTM measures H2S anywhere. The sensor provides superior insights that enable you to adopt a proactive and data-driven approach to odor, corrosion control, chemical injection, in wastewater, biogas, and oil & gas industries.

-

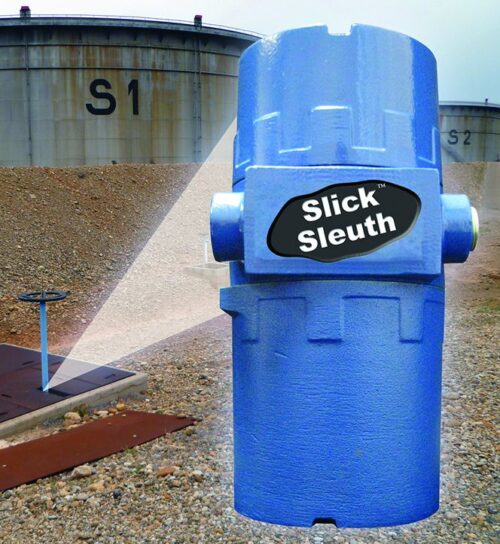

The Slick Sleuth® SS320 and SS320EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS320 product series are used at marine terminals, particularly loading piers and wharves. These sensors are the optimal solution for detection of a wide range of oil-types, on water surfaces as well as dry ground.

-

The Slick Sleuth® SS300 and SS300EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS300 product series are used at refineries, power plants, heavy industries and terminals. These sensors are the optimal solution for detection of oil on water or on ground, concrete and solid surfaces.

-

The World’s most widely used sensor for detection of leaks & spills has been upgraded! The new SS100-LED offers greater range, the latest LED technology, and a field replaceable LED-source which comes with a 5 year warranty.

-

The Slick Sleuth® SS100 is designed for installation in above ground storage tank (AST) facilities, oil terminals, equipment rooms, or anywhere early oil leak and spill detection is needed. Detects a broad range of oil types on water and on dry ground—including spills, slicks, and sheen in tank dikes, sumps, oily water separators, mixing/dispatch points, loading racks, and storm water discharge points and outfalls. Oil detection sensors are used at single points or in a system array to continuously monitor for accidental leaks and spills.

-

Thermostatic steam traps are ideal for sterile and aseptic applications in the pharmaceuticals industry, including pure steam and ultrapure steam applications, clean-in-place, and steam-in-place processes.

-

Sentry single line sample panels are pre-piped assemblies used to simplify the conditioning of steam, water or non-hazardous process samples. With the addition of cooling water, safe and representative samples can be obtained from individual sampling sites that are remotely located throughout the plant or from a small number of samples in a central location.

-

Self-aspirating gas fired igniters guarantee the reliable and safe ignition of main burners in furnaces and boilers if no air supply lines are available. SMITSVONK gas igniters can be equipped with one additional gas tube for increased heat release and flame stability.

-

SBO gravity circulation check valves are installed downstream or upstream in heating and hot water installations to prevent gravity circulation. This ensures that the heating system works correctly, reliably, and at highest efficiency, reducing costs.

-

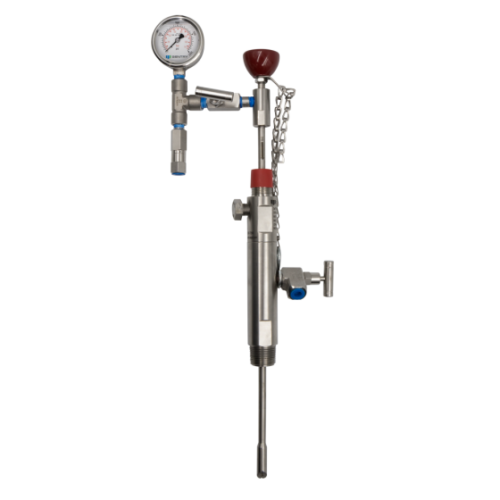

Sentry Saf-T-Vise insertion tools are used to place and retrieve corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers into high-pressure applications without interruption of the system. With their sturdy but light construction—competitor tools can weigh five times more—these tools are operated easily by only one person and are designed to make insertion and retraction under pressure safe, easy and quick.

-

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise probes can be inserted and retracted within a pressurized system for applications that need continual or instant corrosion monitoring. An electrical resistance (ER) probe measures both electrochemical and mechanical corrosion and is suited to corrosive environments with either poor or non-continuous electrolytes, such as vapors, gases, soils, wet hydrocarbons and nonaqueous liquids.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Wafer-type non-return (check) valves with spring, for installation in any position. Ideal for liquids, gases, and vapor applications. GESTRA's RK (wafer-type) non-return valves are for sandwiching between flanges. The valve has a spring to allow installation in any position. The valve self-centering body uses patented centering cams for RK 86/ RK 86A which make installation easier and faster – reducing costs. Our RK non-return valves are ideal for liquids, gases, and vapor applications.

-

The Pony® Sample Conditioning System (PSCS®) is ideal for sampling wet or dry natural gas when a compact solution mounted directly to the sampling probe is preferred. The PSCS contains a self-limiting block heater, Watlow® PID temperature controller, system temperature limiter, and a single or multistage pressure regulator, all mounted inside a Pony® Heated Probe Enclosure. The close coupled system reduces the opportunity for richer gases to condense within sample tubing and protects analyzers from damage by solids or liquids while delivering a representative sample

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

The Mustang P53® Sample Conditioning System is an integral component to provide an Analytically Accurate® solution for natural gas sampling applications. The P53® Sample Conditioning System solves the problem of hydrocarbon liquid condensation from Joule-Thomson cooling in natural gas analysis systems. High pressure natural gas samples are transported at a temperature well above the expected hydrocarbon dew point, which is maintained throughout the pressure reduction process, delivering a representative sample to the analyzers.

-

The Mustang NGL Sample Conditioning System (MNGL®) combines a Mustang® Vaporizer and Mustang® Heated Regulator with a PID temperature controller and a liquid membrane separator to create a robust, single-path pressure regulating and vaporizing sample conditioning system for natural gas liquids.

-

The Mustang® Liquid Sample Pump (MLSP®) enhances Analytically and repeatability of measurements of Natural Gas Liquids (NGL) extracted from a pipeline by a sample probe during sample analysis processing utilizing a metering pump up-stream of the sample conditioning equipment. The Mustang Liquid Sample Pump also reduces lag time of the pressurized fluid prior to introduction to the sample conditioning equipment. The system generates sufficient residual pressure to off-set and overcome the takeoff vacuum (suction pressure) to promote unfiltered bypass flow for fluid reinjection into the pipeline.

-

The Mustang Composite Sampling System is an intermittent, waterless sampling system for liquefied natural gas. The system accumulates a representative sample by capturing small samples at regular intervals, either fixed or proportional to flow rate.