When you need to integrate instrumentation and analytical measurement equipment into a panel, system, or building, Benchmark’s vertically integrated engineering, design and manufacturing services provide a full service, total turnkey solution.

From engineering and design to building and fabrication, our focus has always been making it easy for customers to satisfy their sampling, measuring and monitoring needs with a one-stop-shop experience.

Our Engineering and Design team can work with you and your in-house teams to design an integrated project to meet your end use requirements. We’ll source every single component required to build the system through our preferred vendor network. We then manufacture, integrate, test and certify (when necessary) to ensure the project meets all standard and specification requirements.

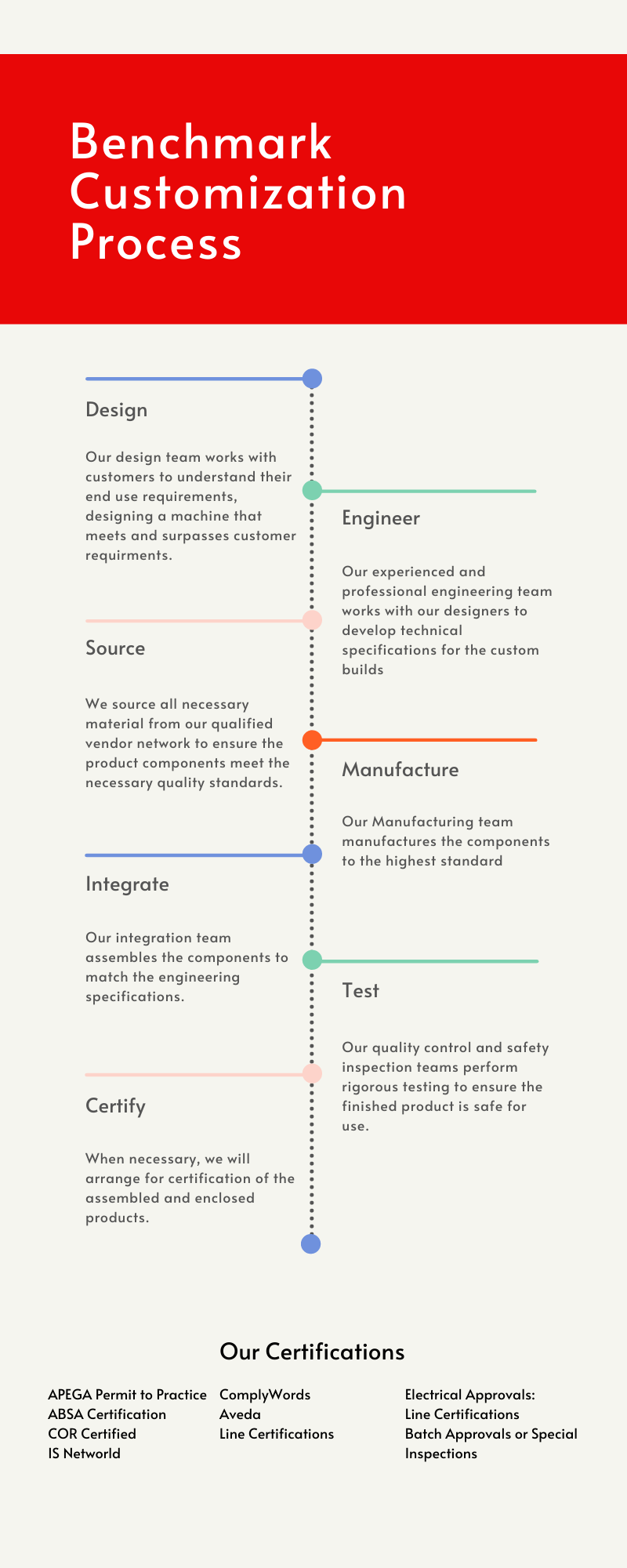

Benchmark’s Customization Process

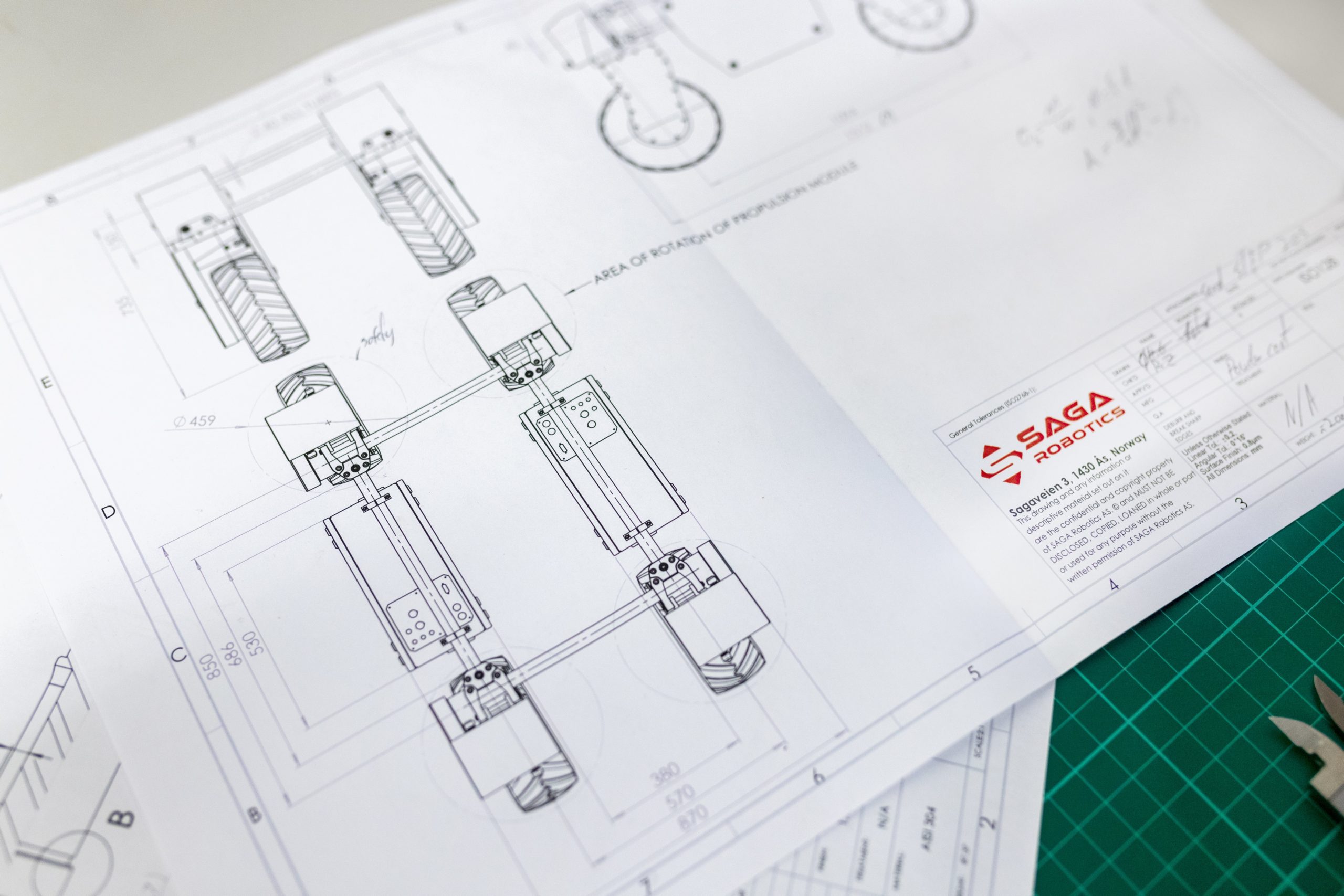

Our design team works with customers to understand their end use requirements design a machine that meets and surpasses customer requirements.

Our experienced and professional engineering team works with the design team to develop technical specifications for the custom builds.

We source all the necessary material from our qualified vendor network to ensure the product components meet the necessary quality standards.

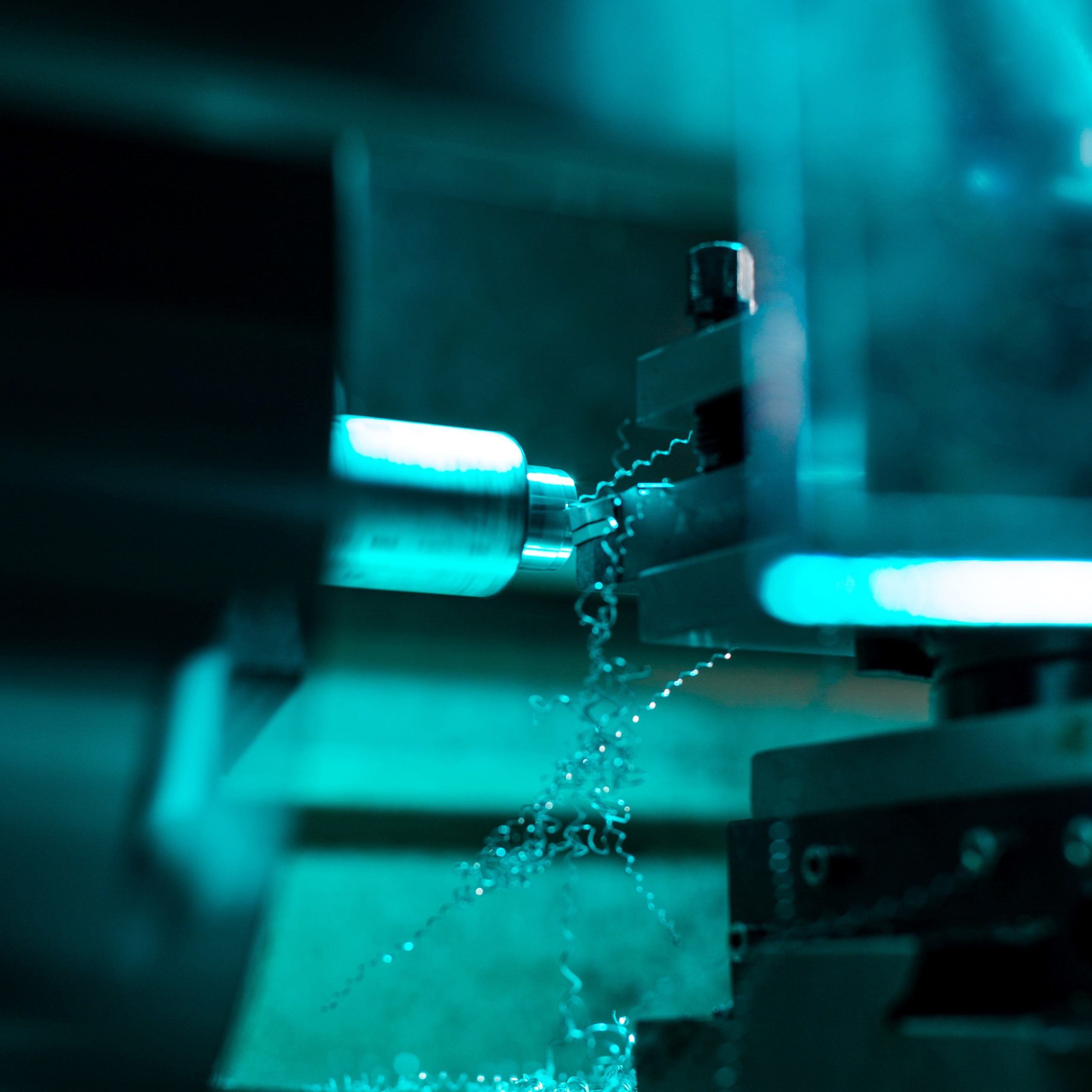

Our manufacturing team manufactures the components to the highest standard.

Our integration team assembles the componenets to match the egineering specifications.

Our quality control and safety inspection teams perform rigorous testing to ensure the finished product is safe for use.

When necessary, we will arrange for certification of the assembled and enclosed products.

Our Certifications

APEGA Permit To Practice

ABSA Certification

IS Networld

ComplyWorks

Aveda

Electrical Approvals:

Line Certifications

Batch Approvals

Special Inspections