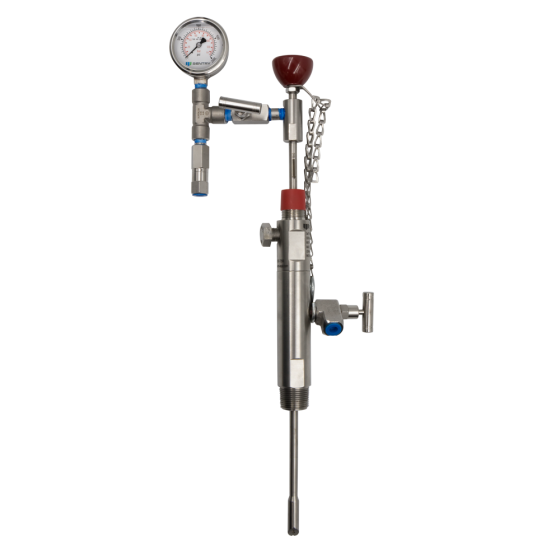

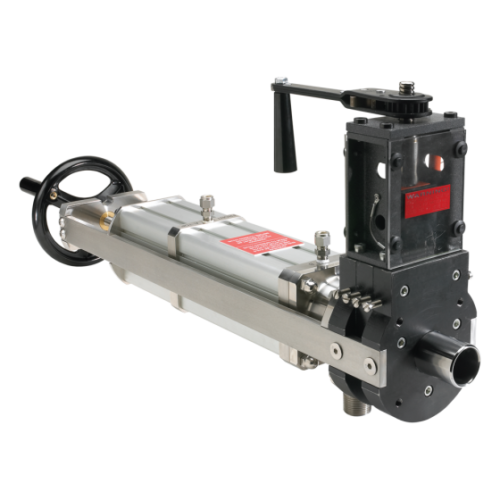

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

Saf-T-Vise Injection and Sample Quills

Description

Description

SENTRY SAF-T-VISE QUILLS – THE SAFEST CHOICE UNDER PRESSURE

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

To operate a Sentry injection & sample quill as a sampler, simply install a sampling valve on the fluid inlet. Gas or liquid samples can be taken from any desired depth without interrupting the product stream flow.

Benefits

Models

| Model | insertion pressure (MOP) | pressure rating (MAP) | temperature rating (seals) | materials |

|---|---|---|---|---|

| STV-LP1-Q | 750 psi at 100°F (52 bar at 38°C) | 2000 psi at 100°F (207 bar at 38°C) | PTFE: 450°F (232°C) | 316/316L SS |

| STV-LP2-Q | 3/8 in: 750 psi at 100°F (52 bar at 38°C) 1/2 in: 420 psi at 100°F (29 bar at 38°C) |

4000 psi at 100°F (275 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP1-Q | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP2-Q | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS |

*Graphoil seals are available for higher temperature applications; contact factory for details

MAP: Maximum Allowable Pressure

MOP: Maximum Operating Pressure

Features

- Process pressure bleeder valve

- Patented locking collet safely secures the shaft within the process stream until released by the operator

- Integrated safety cap or chain, depending on model

- 45-degree bevel with crosscut face

- Designed and manufactured in accordance with ASME B31.3

- Canadian Registration Number available for most models

- Process wetted components comply with NACE MR0175/2009 and are suitable for service in hydrogen sulfide (H2S) environments

| Wetted Materials | 316/316L SS |

|---|