-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

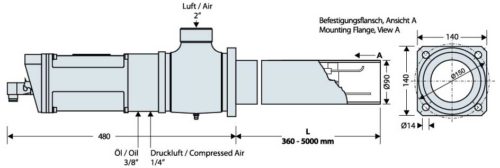

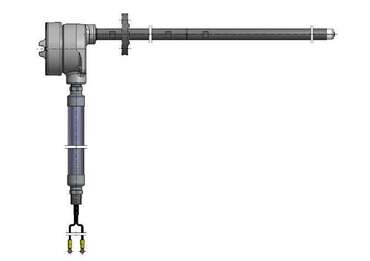

Ignition lance with high voltage cable, guided in a metal hose, for hazardous areas according NEC 500. This design boasts flexible customization for specific installation conditions as well as easily replaceable ignition tips which are specialized for ignition of HFO or at high pressure.

-

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions. Flame front ignition version of this product is also available

-

A flame front generator is a system in which a gas/air mixture is introduced at ground level and flows up a one-inch line to the pilot burner. After filling this line with the mixture it is ignited by a spark. The resulting flame travels to the top of the flare where the pilot burner is ignited.

-

A gas burner boasting a rugged and low-maintenance design with guaranteed electromagnetic compatibility, easy-to-replace electrical components, built-in convenient flame rod, and does not require on-site high-voltage cables. Fuel types include natural gas, conditioned coke over gas, propane, butane, or process gas according to customer preference.

-

Self-aspirating gas fired igniters guarantee the reliable and safe ignition of main burners in furnaces and boilers if no air supply lines are available. SMITSVONK gas igniters can be equipped with one additional gas tube for increased heat release and flame stability.

-

A gas fired igniter boasting compact design with an integrated spark transformer and ionization flame monitor/burner control, a convenient and built in flame rod, guaranteed electromagnetic compatibility, and a rugged low maintenance design that does not require an on-site high voltage cable. Igniters are made in sizes ranging from 2 kW to 10 MW (7000 BTU/hr to 35000000 BTU/hr), and fuel types are tailored to customer preference and analysis.

-

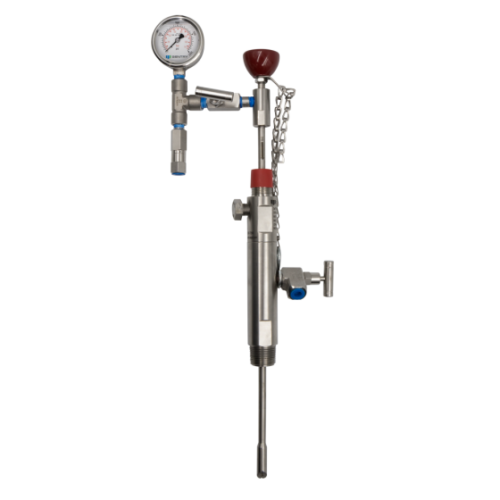

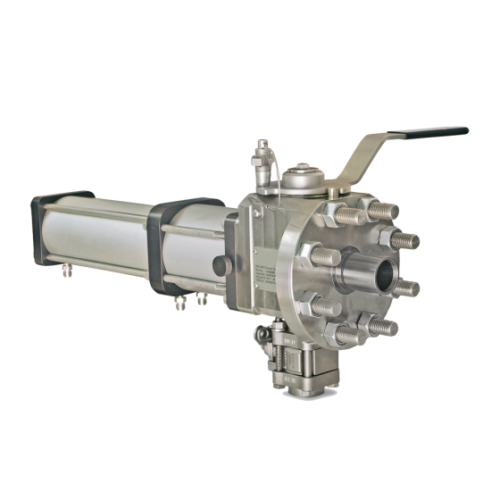

Sentry Saf-T-Vise insertion tools are used to place and retrieve corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers into high-pressure applications without interruption of the system. With their sturdy but light construction—competitor tools can weigh five times more—these tools are operated easily by only one person and are designed to make insertion and retraction under pressure safe, easy and quick.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise probes can be inserted and retracted within a pressurized system for applications that need continual or instant corrosion monitoring. An electrical resistance (ER) probe measures both electrochemical and mechanical corrosion and is suited to corrosive environments with either poor or non-continuous electrolytes, such as vapors, gases, soils, wet hydrocarbons and nonaqueous liquids.

-

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

-

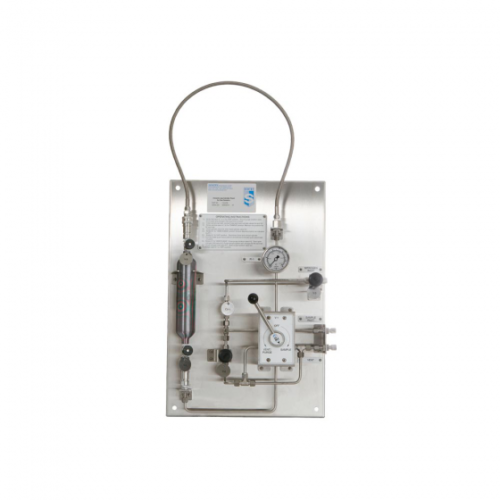

Sentry DPA Series offers easy-to-use drip pot assemblies to collect samples within a pipeline or other pressurized system for the purpose of examining and measuring corrosion products and other contaminants, without interruption to the system. Drip pot assemblies collect the samples for analysis using a container with an interior reservoir for receiving a liquid sample, and a valve assembly coupled to the drip pot.

-

The Sentry Cobra DT closed loop sampler is designed to perform a detector tube measurement as safely, quickly and efficiently as possible. The Cobra DT sampler is designed with safety in mind, with a high-pressure regulator providing operators with a means to lower pressure to a safe level before inserting the detector tube. The 1000 cc cylinder allows a large volume of gas to be chambered so the operator can draw a fresh sample through the detector tube allowing a representative measurement to be collected.

-

The Sentry Cobra SS manual liquid sampler allows for safe and straightforward petroleum and natural gas sampling. The sampler design ensures a representative sample through direct connections to your lines. This Sentry low-emission sampler stands up to water corrosion and meets the highest quality and reliability standards required of petroleum sampling equipment.

-

The Sentry Cobra C manual gas sampler collects representative samples from gas and liquid short-chain hydrocarbon applications. This emission-free sampler uses a multi-ported valve. This valve simplifies the process of taking a sample. Additionally, it keeps the sample's integrity and handles environmental risks.

-

The Sentry MCG sampler is a closed-loop sampler for sampling gas. Closed-loop cylinder sampling is the safest and most effective way to obtain and transport representative samples of gases without danger to the operator or environment. A continuous flow assures representative sampling.

-

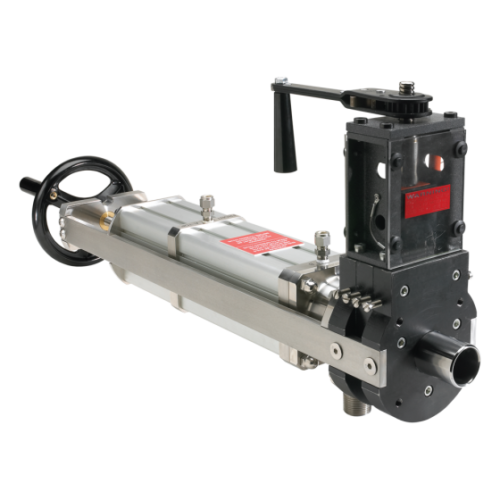

The Sentry ISOLOK SAL-DBB automatic point sampler collects representative liquid and slurry samples in harsh operating conditions, such as oil sand mining. Safety, reliability, convenience and ease of service are all designed into this sampler, which features patented double block and bleed technology.

-

The Sentry ISOLOK SAL-Q automatic point sampler is a heavy-duty, isolatable sampler using ISOLOK proven technology and suitable for oil sands and other mining applications. The Sentry ISOLOK SAL-Q sampler employs the industry-proven Delta double block and bleed, ANSI-rated knife gate valve to isolate the sampler from the process line when the sampler needs servicing.

-

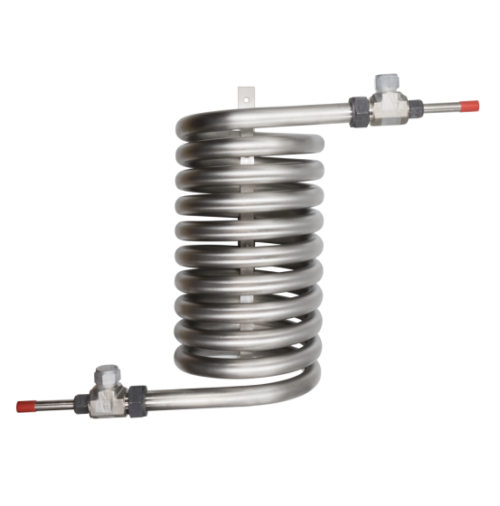

Sentry DTC (dual tube coil) tube-in-tube heat exchangers are spirally wound, full counter flow heat exchangers well suited for a variety of applications where low flow rates of high temperature and/or high pressure fluids need cooling or heating. The sturdy tube-within-a-tube concept uses heavy duty terminal fittings to provide for a plain tube end interface for the inner tube, and a compression connection for the outer tube.

-

The Sentry high-temperature shut-off valve is designed for use with sampling systems to shut off flow when the sample temperature becomes too hot. The valve is suitable for grab sample or instrument applications that could experience a loss of coolant or surges in sample flow rates, which would cause the sample temperture to rise suddenly.

-

The Sentry TSV is a self-contained, mechanical device that protects operators, analyzers and sampling components from high temperature liquids. It is an economical and reliable mechanical replacement for a solenoid shutoff valve and temperature controller, requiring no external source of electricity, air or hydraulics.

-

The Sentry W7950 sparger assembly is used to prepare a sample for taking a degassed cation conductivity measurement.

-

Out of stockSentry single line sample panels are pre-piped assemblies used to simplify the conditioning of steam, water or non-hazardous process samples. With the addition of cooling water, safe and representative samples can be obtained from individual sampling sites that are remotely located throughout the plant or from a small number of samples in a central location.

-

The Sentry W9000 Series sample coolers are designed for small volume hot water samples. The efficient counterflow design provides cooling for samples up to 750°F (399°C) and 3500 psig (241.3 barg), and the simplicity provides maximum cooling at minimal cost. With a compact design, simple installation and high quality materials, the W9000 Series sample coolers are the best low capacity option for small volume hot water samplers of water or other liquids.

-

The Sentry TRW sample cooler cools a sample from a process stream. It may seem simple, but it is a uniquely designed small tube in a shell heat exchanger. The sample to be cooled flows through the tube side of the cooler, and the cooling fluid, usually water, flows through the shell side. The cooled sample then is taken to a laboratory for analysis or piped to in-line process instrumentation for continuous monitoring of properties such as conductivity, pH or other chemical constituents

-

Compact and cost effective transmittance dust and opacity measuring device for monitoring medium to high dust concentrations in dry flue and process gas.

-

The Extrel Atmospheric Pressure Ionization Mass Spectrometer (APIMS) was designed to have reliable and repeatable low parts per trillion detection limits for gas contaminates. The VeraSpec™ Trace system has been the first choice for ultra high purity (UHP) gas contamination analysis and trace pollution studies for over twenty-five years.

-

The MAX300-LG High Performance Laboratory Gas Analyzer combines the analytical capabilities of our high performance industrial Mass Spectrometer for the laboratory. This analyzer offers the Extrel quadrupole performance in an economical package suitable for climate controlled laboratory environments.

-

The MAX300-CAT is a fast, high-sensitivity, quantitative gas analyzer for catalysis, reaction monitoring, and environmental research. This powerful quadrupole system performs high precision quantitative analysis of every component in a gas or vapor mixture, and can be equipped for the fully-automated sampling of 61+ gas channels.

-

The MAX300-EGA quadrupole mass spectrometer is the newest Evolved Gas Analyzer within Extrel’s high performance MAX300 family and is designed for coupling with instrumentation in thermal analysis, pharmaceutical, materials science, and organic chemistry laboratories and features Extrel's industry leading 19mm quadrupole mass filter.

-

The MAX100-BTU provides a rapid, high precision measurement of heating value and gas composition for optimal combustion control and environmental compliance.The MAX100-BTU uses cutting-edge quadrupole mass spectrometer technology to deliver a continuous online analysis of fuel gas and vent streams containing hydrocarbons, H2, CO, CO2, H2O, H2S and other gases. It has the speed necessary to analyze the total composition of the sample and report the Heating Value in seconds.

-

Fast, Accurate, Efficient Mass Spectrometry is a powerful tool for bioreactor monitoring. Changes to the composition of bioreactor or fermentor off-gas provide crucial insight into cellular health and production efficiency. This makes the fast, accurate analysis of CO2, O2, N2, Ar, H2O and other compounds essential for real-time process control. The MAX300-BIO uses cutting edge quadrupole mass spectrometer technology to quantify bioreactor gases from multiple reactors within the facility and reports the data to the control system in real-time.

-

The MAX300-AIR is an industrial gas analyzer optimized for environmental and ambient air monitoring and regulatory compliance. Quadrupole mass spectrometry is extremely sensitive and very fast, allowing for the rapid detection and quantitation of a wide variety of toxic industrial contaminants. The speed of the MAX300-AIR allows one analyzer to measure unlimited compounds and be automated to monitor 160+ sample points, spread throughout the manufacturing site.

-

The MAX300-RTG is a real-time gas analyzer for industrial process control.

- Uses cutting edge quadrupole mass spectrometer technology to deliver continuous online composition monitoring of industrial gas streams.

- Rapid, accurate gas analysis enables high-precision reactor control and increased production efficiency.