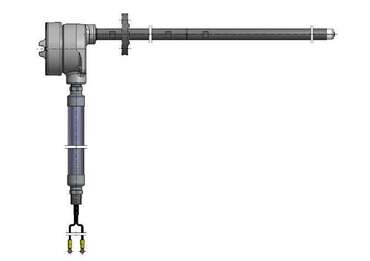

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

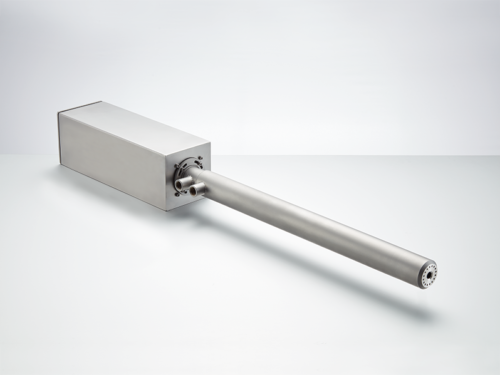

D-GT 800 Flame Sensor

Description

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

Overview

- Optionally available with air/water cooling

- Deployable with high combustion chamber overpressure

- High vibrational stability.

- Conforms to general safety regulations

- Self-monitoring and fail-safe in conjunction with a control unit/burner control

- Connection to the D-UG 120, D-UG 660 control unit and the D-GF 150 burner control

Applications

- Burners with difficult installation conditions for conventional flame sensors or on those whose environmental temperature near the sighting tube is very high

- Power stations

- Chemical industry

- Refineries

- Waste incinerators

- Steam generators

- Heating plants

- Gas turbines

Technical Data

| Operational mode | Intermittent operation, continuous operation and 72-hour operation without permanent supervision |

| Safety | Self-monitoring and fail-safe in conjunction with a control unit/burner control |

| Protection | With cable gland (D-GT 800…/801…-P) IP67, Ex-Version (D-GT 800…/801…/Ex) IP66 |

| Ex-Protection (D-GT 800/801 Ex) | II 2G Ex d T4/T5/T6 |

| Spectral range | UV |

| Viewing angle | 6° |

| Perm. ambient temperature | Without cooling: -20…+120°C Air cooling: -20…+200°C Water cooling: -20…+300°C |

| Vibration | 10 g |

| Dimensions | Ø100 mm; length approx. 190 mm |

| Weight | Without cooling: approx. 1.5 kg, with cooling: approx. 2.0 kg |

| Max. combustion chamber overpressure | 30 bar |

| Sighting tube connection | ¾“ NPT (F) |

| Cooling connection | ½“ NPT (F) |

Resources

GENERAL INFORMATION

PRODUCT INFORMATION

Accessories

- UV-A, UV-B and IR test light source 230 V/50 Hz (D-ZS 093)

- Terminal box for connecting the flame sensor (D-ZS 140, D-ZS 141)