InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.

-

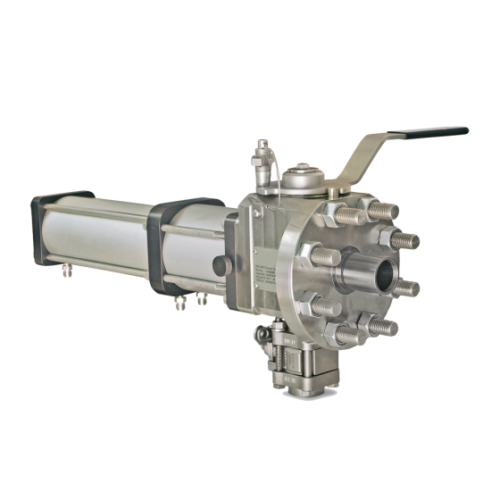

The Sentry ISOLOK SAL-DBB automatic point sampler collects representative liquid and slurry samples in harsh operating conditions, such as oil sand mining. Safety, reliability, convenience and ease of service are all designed into this sampler, which features patented double block and bleed technology.

-

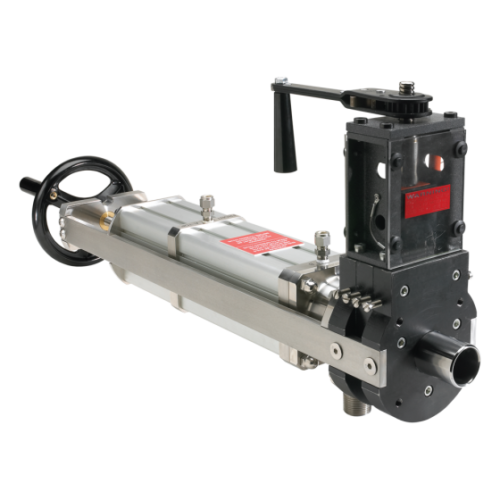

The Sentry ISOLOK SAL-Q automatic point sampler is a heavy-duty, isolatable sampler using ISOLOK proven technology and suitable for oil sands and other mining applications. The Sentry ISOLOK SAL-Q sampler employs the industry-proven Delta double block and bleed, ANSI-rated knife gate valve to isolate the sampler from the process line when the sampler needs servicing.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

The Packing Leak Detector (PLD) helps reduce leak rates to near zero. Methane leaks from compressor packing glands are common and result in lost revenue and can lead to environmental penalties. The PLD provides mechanical or digital notification of a leak allowing for early intervention and remedy.

-

The MAX100-BTU provides a rapid, high precision measurement of heating value and gas composition for optimal combustion control and environmental compliance.The MAX100-BTU uses cutting-edge quadrupole mass spectrometer technology to deliver a continuous online analysis of fuel gas and vent streams containing hydrocarbons, H2, CO, CO2, H2O, H2S and other gases. It has the speed necessary to analyze the total composition of the sample and report the Heating Value in seconds.

-

The MAX300-AIR is an industrial gas analyzer optimized for environmental and ambient air monitoring and regulatory compliance. Quadrupole mass spectrometry is extremely sensitive and very fast, allowing for the rapid detection and quantitation of a wide variety of toxic industrial contaminants. The speed of the MAX300-AIR allows one analyzer to measure unlimited compounds and be automated to monitor 160+ sample points, spread throughout the manufacturing site.

-

Fast, Accurate, Efficient Mass Spectrometry is a powerful tool for bioreactor monitoring. Changes to the composition of bioreactor or fermentor off-gas provide crucial insight into cellular health and production efficiency. This makes the fast, accurate analysis of CO2, O2, N2, Ar, H2O and other compounds essential for real-time process control. The MAX300-BIO uses cutting edge quadrupole mass spectrometer technology to quantify bioreactor gases from multiple reactors within the facility and reports the data to the control system in real-time.

-

The MAX300-CAT is a fast, high-sensitivity, quantitative gas analyzer for catalysis, reaction monitoring, and environmental research. This powerful quadrupole system performs high precision quantitative analysis of every component in a gas or vapor mixture, and can be equipped for the fully-automated sampling of 61+ gas channels.

-

The MAX300-EGA quadrupole mass spectrometer is the newest Evolved Gas Analyzer within Extrel’s high performance MAX300 family and is designed for coupling with instrumentation in thermal analysis, pharmaceutical, materials science, and organic chemistry laboratories and features Extrel's industry leading 19mm quadrupole mass filter.

-

The MAX300-LG High Performance Laboratory Gas Analyzer combines the analytical capabilities of our high performance industrial Mass Spectrometer for the laboratory. This analyzer offers the Extrel quadrupole performance in an economical package suitable for climate controlled laboratory environments.

-

The MAX300-RTG is a real-time gas analyzer for industrial process control.

- Uses cutting edge quadrupole mass spectrometer technology to deliver continuous online composition monitoring of industrial gas streams.

- Rapid, accurate gas analysis enables high-precision reactor control and increased production efficiency.

-

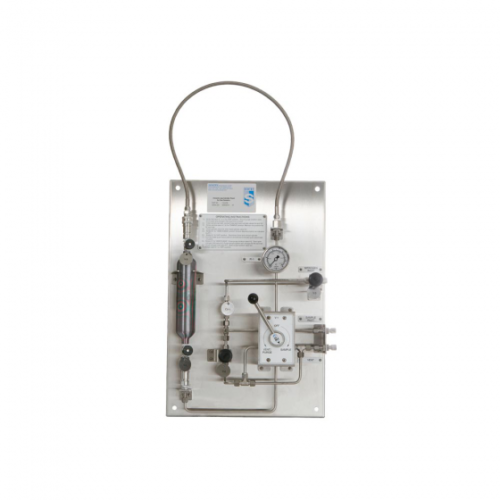

The Sentry MCG sampler is a closed-loop sampler for sampling gas. Closed-loop cylinder sampling is the safest and most effective way to obtain and transport representative samples of gases without danger to the operator or environment. A continuous flow assures representative sampling.

-

The Mustang Intelligent Vaporizer Sampling System is a patented technology system designed to vaporize liquid, providing a fresh sample to a continuous online analyzer. This system is designed with enhanced sample quality, through controlled vaporization, accumulation, and homogenization, accomplished through multiple stages.

-

The Mustang Composite Sampling System is an intermittent, waterless sampling system for liquefied natural gas. The system accumulates a representative sample by capturing small samples at regular intervals, either fixed or proportional to flow rate.

-

The Mustang® Liquid Sample Pump (MLSP®) enhances Analytically and repeatability of measurements of Natural Gas Liquids (NGL) extracted from a pipeline by a sample probe during sample analysis processing utilizing a metering pump up-stream of the sample conditioning equipment. The Mustang Liquid Sample Pump also reduces lag time of the pressurized fluid prior to introduction to the sample conditioning equipment. The system generates sufficient residual pressure to off-set and overcome the takeoff vacuum (suction pressure) to promote unfiltered bypass flow for fluid reinjection into the pipeline.

-

The Mustang NGL Sample Conditioning System (MNGL®) combines a Mustang® Vaporizer and Mustang® Heated Regulator with a PID temperature controller and a liquid membrane separator to create a robust, single-path pressure regulating and vaporizing sample conditioning system for natural gas liquids.

-

The Mustang P53® Sample Conditioning System is an integral component to provide an Analytically Accurate® solution for natural gas sampling applications. The P53® Sample Conditioning System solves the problem of hydrocarbon liquid condensation from Joule-Thomson cooling in natural gas analysis systems. High pressure natural gas samples are transported at a temperature well above the expected hydrocarbon dew point, which is maintained throughout the pressure reduction process, delivering a representative sample to the analyzers.

-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

The Pony® Sample Conditioning System (PSCS®) is ideal for sampling wet or dry natural gas when a compact solution mounted directly to the sampling probe is preferred. The PSCS contains a self-limiting block heater, Watlow® PID temperature controller, system temperature limiter, and a single or multistage pressure regulator, all mounted inside a Pony® Heated Probe Enclosure. The close coupled system reduces the opportunity for richer gases to condense within sample tubing and protects analyzers from damage by solids or liquids while delivering a representative sample

-

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.