The Mustang Intelligent Vaporizer Sampling System is a patented technology system designed to vaporize liquid, providing a fresh sample to a continuous online analyzer. This system is designed with enhanced sample quality, through controlled vaporization, accumulation, and homogenization, accomplished through multiple stages.

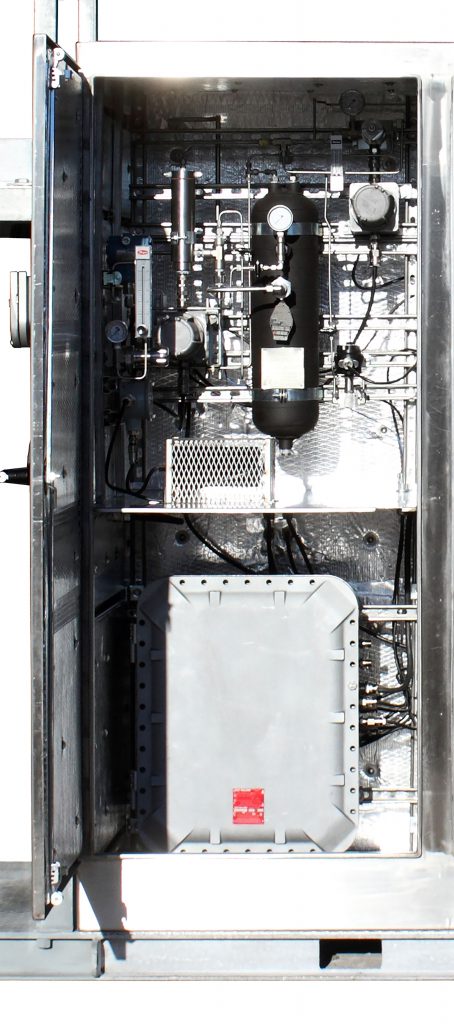

Mustang Intelligent Vaporizer Sampling System® – Model 3 (MIV3®)

The Mustang Intelligent Vaporizer Sample Conditioning System® – Model 3 (MIV3®) provides a fresh spot gas sample from a Liquefied Natural Gas stream for non-custody transfer applications. The MIV3 operates manually and delivers an Analytically Accurate® sample through controlled vaporization, accumulation, and homogenization of a multiple stage system.

VAPORIZATION & REMIXING STAGES

VAPORIZING: Available in a single-path design. The MIV3 flash vaporizes liquid samples for introduction into gas analysis systems. Liquid samples are maintained near line conditions until reaching a flash chamber within the vaporizer, preventing pre-vaporization. The energy for vaporization is provided by an electric cartridge heater with sufficiently large surface area to maintain a stable gas temperature throughout the process and send the sample to the Mustang® Accumulator for restructuring.

ACCUMULATING: The Mustang® Accumulator Cylinder is designed with a special impingement tube to aid in the absorption of pressure pulsations and homogenization of gasified LNG.

A vapor return bypass flow control system is controlled by an armored flowmeter with a valve.The vapor is sent to the vapor return or flare.

PRESSURE REGULATING: This system uses a non-heated regulator to reduce the pressure to the sample cylinders.

Features

- Continuous gas flow design

- Integral flow restrictor on inlet

- NEMA 4X Enclosure

Benefits

- Instantaneous vaporization of a liquid sample

- Prevents post-vaporization hydrocarbon liquid dropout

- Provides a homogenous sample

- Provides an accurate and reliable representative sample

- Easy maintenance

- Supplies manual grab samples to multiple analyzers

- Dedicated software platform for operating, monitoring, trending, and reporting (see SoftView® Monitor)