-

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise probes can be inserted and retracted within a pressurized system for applications that need continual or instant corrosion monitoring. An electrical resistance (ER) probe measures both electrochemical and mechanical corrosion and is suited to corrosive environments with either poor or non-continuous electrolytes, such as vapors, gases, soils, wet hydrocarbons and nonaqueous liquids.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

-

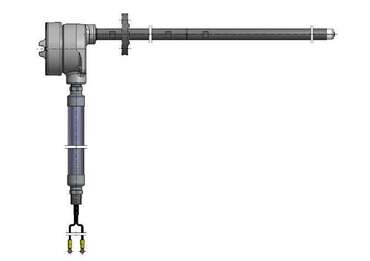

Sentry Saf-T-Vise insertion tools are used to place and retrieve corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers into high-pressure applications without interruption of the system. With their sturdy but light construction—competitor tools can weigh five times more—these tools are operated easily by only one person and are designed to make insertion and retraction under pressure safe, easy and quick.

-

A gas fired igniter boasting compact design with an integrated spark transformer and ionization flame monitor/burner control, a convenient and built in flame rod, guaranteed electromagnetic compatibility, and a rugged low maintenance design that does not require an on-site high voltage cable. Igniters are made in sizes ranging from 2 kW to 10 MW (7000 BTU/hr to 35000000 BTU/hr), and fuel types are tailored to customer preference and analysis.

-

Self-aspirating gas fired igniters guarantee the reliable and safe ignition of main burners in furnaces and boilers if no air supply lines are available. SMITSVONK gas igniters can be equipped with one additional gas tube for increased heat release and flame stability.

-

A gas burner boasting a rugged and low-maintenance design with guaranteed electromagnetic compatibility, easy-to-replace electrical components, built-in convenient flame rod, and does not require on-site high-voltage cables. Fuel types include natural gas, conditioned coke over gas, propane, butane, or process gas according to customer preference.

-

A flame front generator is a system in which a gas/air mixture is introduced at ground level and flows up a one-inch line to the pilot burner. After filling this line with the mixture it is ignited by a spark. The resulting flame travels to the top of the flare where the pilot burner is ignited.

-

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions. Flame front ignition version of this product is also available

-

Ignition lance with high voltage cable, guided in a metal hose, for hazardous areas according NEC 500. This design boasts flexible customization for specific installation conditions as well as easily replaceable ignition tips which are specialized for ignition of HFO or at high pressure.

-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

-

Flame sensor (flame scanner) for the monitoring of gas, oil and coal flames, primarily in single burner view applications.

-

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

-

Self-monitoring and fail-safe compact flame monitor for the monitoring of gas, oil and coal flames with integrated UV, VIS or IR flame sensor, primarily in single burner view applications.

-

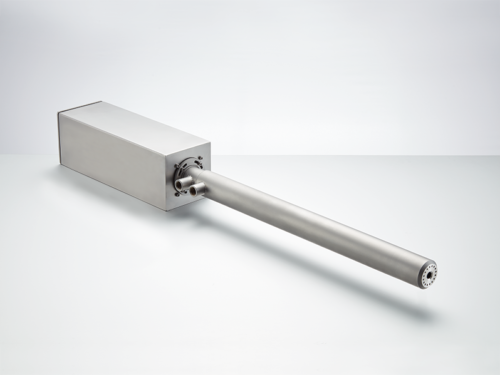

Digital Furnace Camera delivers brilliant live video directly out of the combustion chamber. Available in air or water cooled versions for process temperatures up to 2000°C. The D-FS 50 can be combined with the D-VT 50 Video System or the D-VTA 200 Thermography Analysis System.

-

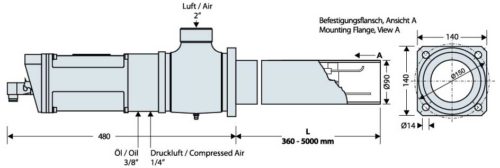

The digital furnace sensor D-FS2 delivers high definition live images directly out of the combustion chamber. The D-FS2 VIS with high resolution colour video is available as water or air cooled version. The furnace sensor D-FS2 is designed for the use with a retraction unit. All versions can be extended with the D-VTA 200 software to a thermography and analysis system.

-

Measuring system for continuous evaluation of flow velocity and flow direction in tunnels. Ultrasonic sensors for tunnel ventilation control system. Reliable measurement across the tunnel profile. Two identical sensors alternately transmit and receive ultrasonic pulses. The system evaluates the transition times dependent on direction and calculates flow speed. D-FL 220T requires extremely low maintenance.

-

Ambient air particulate monitor to detect TSP, PM10 or PM2.5 in ambient air for use in industrial or governmental ambient air monitoring networks.

-

Suitability-tested and certified impact pressure system to measure velocity and volume flow of dry flue gas or process gas in pipes or ducts.

-

Suitability tested and certified ultrasonic measuring system to measure the velocity and the volume flow of flue gas or process gas in pipes or ducts, especially for wet and aggressive smoke emissions.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.