-

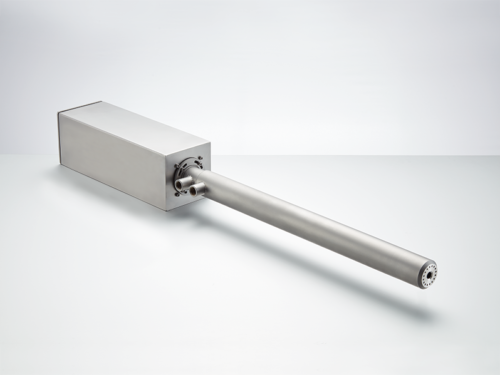

The TD-2500 combines ultrasonics and a time-tested insertion probe to offer the ultimate in early detection of high concentrations, or slugs, of oil in waste water. Ultrasonic technology measures oil at high concentrations, typically seen after oil/water separation, is sensitive to droplets, solids or gas bubbles and is easier to maintain than optical technologies.

-

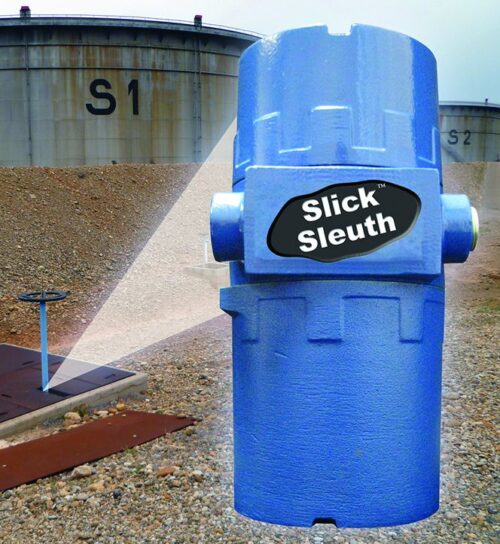

The World’s most widely used sensor for detection of leaks & spills has been upgraded! The new SS100-LED offers greater range, the latest LED technology, and a field replaceable LED-source which comes with a 5 year warranty.

-

The Slick Sleuth® SS320 and SS320EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS320 product series are used at marine terminals, particularly loading piers and wharves. These sensors are the optimal solution for detection of a wide range of oil-types, on water surfaces as well as dry ground.

-

The Slick Sleuth® SS300 and SS300EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS300 product series are used at refineries, power plants, heavy industries and terminals. These sensors are the optimal solution for detection of oil on water or on ground, concrete and solid surfaces.

-

The Slick Sleuth® SS100 is designed for installation in above ground storage tank (AST) facilities, oil terminals, equipment rooms, or anywhere early oil leak and spill detection is needed. Detects a broad range of oil types on water and on dry ground—including spills, slicks, and sheen in tank dikes, sumps, oily water separators, mixing/dispatch points, loading racks, and storm water discharge points and outfalls. Oil detection sensors are used at single points or in a system array to continuously monitor for accidental leaks and spills.

-

The SulfiLoggerTM measures H2S anywhere. The sensor provides superior insights that enable you to adopt a proactive and data-driven approach to odor, corrosion control, chemical injection, in wastewater, biogas, and oil & gas industries.

-

The Packing Leak Detector (PLD) helps reduce leak rates to near zero. Methane leaks from compressor packing glands are common and result in lost revenue and can lead to environmental penalties. The PLD provides mechanical or digital notification of a leak allowing for early intervention and remedy.

-

The TD-4100XDC General Purpose oil in water monitor is a lower cost version of the industry standard TD-4100XDC and is designed for use in non-explosive atmospheres. It was designed for normally clean water applications, or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems.

-

The TD-4100XDC is a closed cell version of the rugged, world industry standard TD-4100XD Oil in Water Monitor. It was designed for normally clean water applications or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It utilizes a clear tube flow cell to contain the sample water at pressure to prevent oxygen contamination in steam systems and to return the sample to the process at pressure. It uses a unique internal cell condition monitor to alert operations of the need for cleaning or to trigger the optional onboard cleaning system. As with all Benchmark Measurement Solutions monitors, it includes a field validation method.

-

The TD-4100XD General Purpose monitor is a lower cost version of the industry standard TD-4100XD and is designed for use in non-explosive atmospheres. It was designed for dirty water applications and uses our standard EZ Access noncontact flow cell for lower maintenance. Field validation is via our CheckPOINT™ solid calibration check standard.

-

The TD-4100XD is a ruggedized version of the TD-4100 continuous online oil in water monitor. The XD is designed specifically for offshore oil production, refining, petrochemical, mining, and other industries that require robust online hardware for severe duty and hazardous area locations. The monitor is skid or wall mounted and constructed of 316 stainless steel.

-

Benchmark Measurement Solutions is proud to present the CF-200 Algae Monitor. Using the C-Fluor fluorescence probe, the online monitor is fully integrated and ready to detect Chlorophyll A in fresh or sea water.

-

The TD-120 Oil in Water Monitor is ideal for detection of oil leaks from heat exchangers—protecting boilers, water intakes and membrane systems—as well as optimizing water treatment systems. With low detection limits and extended measurement range, the TD-120 provides the necessary tools and ease of use to meet today’s complex oil in water measurement needs.

-

Benchmark Measurement Solutions, formerly Turner Designs Hydrocarbon Instruments, is proud to introduce the new standard in grab sample oil in water analysis with the TD-550 oil in water analyzer. The TD-550 is suitable for crude oils and other heavy oils with a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers. Related product, the TD-560, includes the same optical channel of the TD-550 along with a second optical channel for detecting lighter hydrocarbons such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol.

-

Benchmark Measurement Solutions, formerly Turner Designs Hydrocarbon Instruments, proudly announces the all new dual-channel TD-560 Oil in Water Analyzer. In addition to the optical channel found in the TD-550, suitable for crude and other heavy oils, the TD-560 adds a second channel for detecting lighter hydrocarbons, such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol. The TD-560 offers a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers.

-

Orbital is a customized solutions provider. Orbital’s design engineers will work alongside you to develop an analytical system that perfectly fits your needs. GasPT, or "Gas Properties Transmitter," is an online analyzer that provides the following physical properties of natural gas:

- Calorific Value (CV) / British Thermal Unit (BTU)

- Wobbe Index (WI)

- Relative Density (RD)

- Compression Factor (Z)

- Methane Number (MN)

- Total Air Requirements (TAR)

- MON

- SOS

-

The Mustang® Liquid Sample Pump (MLSP®) enhances Analytically and repeatability of measurements of Natural Gas Liquids (NGL) extracted from a pipeline by a sample probe during sample analysis processing utilizing a metering pump up-stream of the sample conditioning equipment. The Mustang Liquid Sample Pump also reduces lag time of the pressurized fluid prior to introduction to the sample conditioning equipment. The system generates sufficient residual pressure to off-set and overcome the takeoff vacuum (suction pressure) to promote unfiltered bypass flow for fluid reinjection into the pipeline.

-

The Mustang NGL Sample Conditioning System (MNGL®) combines a Mustang® Vaporizer and Mustang® Heated Regulator with a PID temperature controller and a liquid membrane separator to create a robust, single-path pressure regulating and vaporizing sample conditioning system for natural gas liquids.

-

The Mustang Composite Sampling System is an intermittent, waterless sampling system for liquefied natural gas. The system accumulates a representative sample by capturing small samples at regular intervals, either fixed or proportional to flow rate.

-

The Mustang Intelligent Vaporizer Sampling System is a patented technology system designed to vaporize liquid, providing a fresh sample to a continuous online analyzer. This system is designed with enhanced sample quality, through controlled vaporization, accumulation, and homogenization, accomplished through multiple stages.

-

The Mustang P53® Sample Conditioning System is an integral component to provide an Analytically Accurate® solution for natural gas sampling applications. The P53® Sample Conditioning System solves the problem of hydrocarbon liquid condensation from Joule-Thomson cooling in natural gas analysis systems. High pressure natural gas samples are transported at a temperature well above the expected hydrocarbon dew point, which is maintained throughout the pressure reduction process, delivering a representative sample to the analyzers.

-

The Pony® Sample Conditioning System (PSCS®) is ideal for sampling wet or dry natural gas when a compact solution mounted directly to the sampling probe is preferred. The PSCS contains a self-limiting block heater, Watlow® PID temperature controller, system temperature limiter, and a single or multistage pressure regulator, all mounted inside a Pony® Heated Probe Enclosure. The close coupled system reduces the opportunity for richer gases to condense within sample tubing and protects analyzers from damage by solids or liquids while delivering a representative sample

-

InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

Suitability tested and certified ultrasonic measuring system to measure the velocity and the volume flow of flue gas or process gas in pipes or ducts, especially for wet and aggressive smoke emissions.

-

Suitability-tested and certified impact pressure system to measure velocity and volume flow of dry flue gas or process gas in pipes or ducts.

-

Compact and cost effective transmittance dust and opacity measuring device for monitoring medium to high dust concentrations in dry flue and process gas.

-

Ambient air particulate monitor to detect TSP, PM10 or PM2.5 in ambient air for use in industrial or governmental ambient air monitoring networks.

-

Measuring system for continuous evaluation of flow velocity and flow direction in tunnels. Ultrasonic sensors for tunnel ventilation control system. Reliable measurement across the tunnel profile. Two identical sensors alternately transmit and receive ultrasonic pulses. The system evaluates the transition times dependent on direction and calculates flow speed. D-FL 220T requires extremely low maintenance.

-

The digital furnace sensor D-FS2 delivers high definition live images directly out of the combustion chamber. The D-FS2 VIS with high resolution colour video is available as water or air cooled version. The furnace sensor D-FS2 is designed for the use with a retraction unit. All versions can be extended with the D-VTA 200 software to a thermography and analysis system.

-

Digital Furnace Camera delivers brilliant live video directly out of the combustion chamber. Available in air or water cooled versions for process temperatures up to 2000°C. The D-FS 50 can be combined with the D-VT 50 Video System or the D-VTA 200 Thermography Analysis System.

-

Self-monitoring and fail-safe compact flame monitor for the monitoring of gas, oil and coal flames with integrated UV, VIS or IR flame sensor, primarily in single burner view applications.

-

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

-

Flame sensor (flame scanner) for the monitoring of gas, oil and coal flames, primarily in single burner view applications.

-

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.