-

GESTRA's GCV general-purpose control valves are engineered to provide solutions for steam, condensate, and other industrial fluid, as well as gas applications and processes. These general-purpose control valves reliably and precisely control temperature and pressure within your processes. GCV valves are available with electric or pneumatic actuator, positioners, and compressed air filter/regulators.

-

Save energy and control your cooling-water return temperature with GESTRA's self-acting mechanical control valve CW (GESTRAMAT). GESTRA's CW cooling-water control valves (GESTRAMAT) help you to save energy by reducing the cooling-water flow to a minimum, and keeping the discharge temperature to the maximum permissible value. These control valves are self-acting and sense the discharge temperature by the integral regulator, so you can reduce operating costs.

-

The swing-plate check valve is a cost-effective way to prevent backflow in your pipelines and other industrial applications for use with a wide range of fluids such as gases, liquids and steams.

-

Wafer-type non-return (check) valves with spring, for installation in any position. Ideal for liquids, gases, and vapor applications. GESTRA's RK (wafer-type) non-return valves are for sandwiching between flanges. The valve has a spring to allow installation in any position. The valve self-centering body uses patented centering cams for RK 86/ RK 86A which make installation easier and faster – reducing costs. Our RK non-return valves are ideal for liquids, gases, and vapor applications.

-

SBO gravity circulation check valves are installed downstream or upstream in heating and hot water installations to prevent gravity circulation. This ensures that the heating system works correctly, reliably, and at highest efficiency, reducing costs.

-

With a low pressure drip and excellent sealing, dual-plate check valves prevent the risk of backflow in liquid and gas lines.

-

Thermostatic steam traps are ideal for sterile and aseptic applications in the pharmaceuticals industry, including pure steam and ultrapure steam applications, clean-in-place, and steam-in-place processes.

-

Compact thermodynamic steam traps are ideal for draining heating processes with small load fluctuations, including saturated and superheated steam systems, steam tracing, and air heaters.

-

Suited to steam-regulated heat exchangers, vacuum systems, drying cylinders, steam dryers and systems with very low operating or differential pressures, GESTRA's ball float steam traps remove condensate from steam, cold condensate, and distillates.

-

Highly responsive steam traps with a membrane regulator are ideal for saturated steam systems, steam tracing, heating coils, air heaters, steam rollers, irons, and tire presses. This makes it suitable for heat exchangers where efficient operation is not adversely affected by minimal condensate build-up.

-

InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

Suitability tested and certified ultrasonic measuring system to measure the velocity and the volume flow of flue gas or process gas in pipes or ducts, especially for wet and aggressive smoke emissions.

-

Suitability-tested and certified impact pressure system to measure velocity and volume flow of dry flue gas or process gas in pipes or ducts.

-

Ambient air particulate monitor to detect TSP, PM10 or PM2.5 in ambient air for use in industrial or governmental ambient air monitoring networks.

-

Measuring system for continuous evaluation of flow velocity and flow direction in tunnels. Ultrasonic sensors for tunnel ventilation control system. Reliable measurement across the tunnel profile. Two identical sensors alternately transmit and receive ultrasonic pulses. The system evaluates the transition times dependent on direction and calculates flow speed. D-FL 220T requires extremely low maintenance.

-

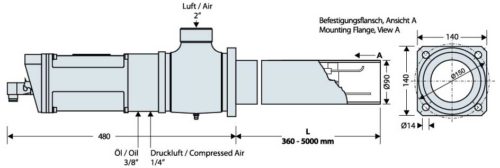

The digital furnace sensor D-FS2 delivers high definition live images directly out of the combustion chamber. The D-FS2 VIS with high resolution colour video is available as water or air cooled version. The furnace sensor D-FS2 is designed for the use with a retraction unit. All versions can be extended with the D-VTA 200 software to a thermography and analysis system.

-

Digital Furnace Camera delivers brilliant live video directly out of the combustion chamber. Available in air or water cooled versions for process temperatures up to 2000°C. The D-FS 50 can be combined with the D-VT 50 Video System or the D-VTA 200 Thermography Analysis System.

-

Self-monitoring and fail-safe compact flame monitor for the monitoring of gas, oil and coal flames with integrated UV, VIS or IR flame sensor, primarily in single burner view applications.

-

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

-

Flame sensor (flame scanner) for the monitoring of gas, oil and coal flames, primarily in single burner view applications.

-

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.