Chemical Injection Pumps and Controllers

- TXAM Pumps manufactures and sells chemical injection pumps for a wide range of applications in the Oil and Gas industry.

- They offer a full line of Solar & AC pumps as well as Class 1, Division 2 options for hazardous areas.

- TXAM Pumps also offers Beam and Pneumatic Pumps to meet your Chemical Injection needs.

- They manufacture multi-point chemical injection systems that allow you to control multiple injection points with a single pump.

- Designed to meet your specific needs, we can provide chemical injection for up to 16 points, all controlled remotely through their UPC or TSP600N Controllers.

Products

-

The Mustang® Liquid Sample Pump (MLSP®) enhances Analytically and repeatability of measurements of Natural Gas Liquids (NGL) extracted from a pipeline by a sample probe during sample analysis processing utilizing a metering pump up-stream of the sample conditioning equipment. The Mustang Liquid Sample Pump also reduces lag time of the pressurized fluid prior to introduction to the sample conditioning equipment. The system generates sufficient residual pressure to off-set and overcome the takeoff vacuum (suction pressure) to promote unfiltered bypass flow for fluid reinjection into the pipeline.

-

The Mustang NGL Sample Conditioning System (MNGL®) combines a Mustang® Vaporizer and Mustang® Heated Regulator with a PID temperature controller and a liquid membrane separator to create a robust, single-path pressure regulating and vaporizing sample conditioning system for natural gas liquids.

-

The Mustang P53® Sample Conditioning System is an integral component to provide an Analytically Accurate® solution for natural gas sampling applications. The P53® Sample Conditioning System solves the problem of hydrocarbon liquid condensation from Joule-Thomson cooling in natural gas analysis systems. High pressure natural gas samples are transported at a temperature well above the expected hydrocarbon dew point, which is maintained throughout the pressure reduction process, delivering a representative sample to the analyzers.

-

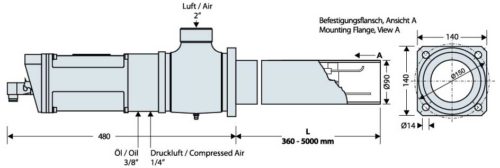

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

The Pony® Sample Conditioning System (PSCS®) is ideal for sampling wet or dry natural gas when a compact solution mounted directly to the sampling probe is preferred. The PSCS contains a self-limiting block heater, Watlow® PID temperature controller, system temperature limiter, and a single or multistage pressure regulator, all mounted inside a Pony® Heated Probe Enclosure. The close coupled system reduces the opportunity for richer gases to condense within sample tubing and protects analyzers from damage by solids or liquids while delivering a representative sample

-

The design of the Optograf process analyzer incorporates customer requirements for serviceability and hazard-area certification, provides a compact footprint, and minimizes utilities consumption. The high optical efficiency of the Optograf process Raman analyzer makes it ideal for measurement of gas-phase samples.

-

Wafer-type non-return (check) valves with spring, for installation in any position. Ideal for liquids, gases, and vapor applications. GESTRA's RK (wafer-type) non-return valves are for sandwiching between flanges. The valve has a spring to allow installation in any position. The valve self-centering body uses patented centering cams for RK 86/ RK 86A which make installation easier and faster – reducing costs. Our RK non-return valves are ideal for liquids, gases, and vapor applications.

-

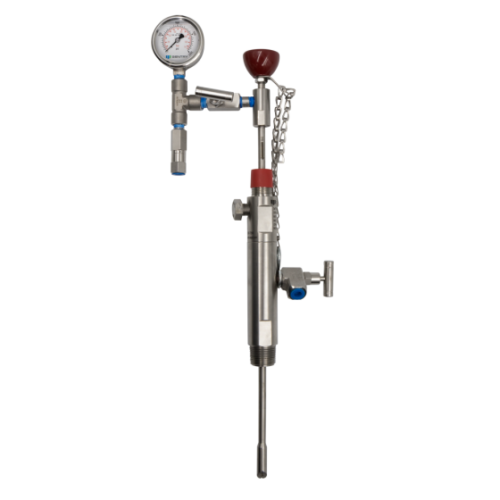

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise probes can be inserted and retracted within a pressurized system for applications that need continual or instant corrosion monitoring. An electrical resistance (ER) probe measures both electrochemical and mechanical corrosion and is suited to corrosive environments with either poor or non-continuous electrolytes, such as vapors, gases, soils, wet hydrocarbons and nonaqueous liquids.

-

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

-

The Mustang® Liquid Sample Pump (MLSP®) enhances Analytically and repeatability of measurements of Natural Gas Liquids (NGL) extracted from a pipeline by a sample probe during sample analysis processing utilizing a metering pump up-stream of the sample conditioning equipment. The Mustang Liquid Sample Pump also reduces lag time of the pressurized fluid prior to introduction to the sample conditioning equipment. The system generates sufficient residual pressure to off-set and overcome the takeoff vacuum (suction pressure) to promote unfiltered bypass flow for fluid reinjection into the pipeline.

-

The Mustang NGL Sample Conditioning System (MNGL®) combines a Mustang® Vaporizer and Mustang® Heated Regulator with a PID temperature controller and a liquid membrane separator to create a robust, single-path pressure regulating and vaporizing sample conditioning system for natural gas liquids.

-

The Mustang P53® Sample Conditioning System is an integral component to provide an Analytically Accurate® solution for natural gas sampling applications. The P53® Sample Conditioning System solves the problem of hydrocarbon liquid condensation from Joule-Thomson cooling in natural gas analysis systems. High pressure natural gas samples are transported at a temperature well above the expected hydrocarbon dew point, which is maintained throughout the pressure reduction process, delivering a representative sample to the analyzers.

-

An oil fired igniter that showcases a compact design with integrated ignition module and ionization flame monitor/burner control with a built-in and convenient flame rod. This product also guarantees electromagnetic compatibility and also does not require on-site high-voltage cabling. Rugged and low maintenance in design, this product is able to accept extra light fuel in propane, butane, natural gas, or diesel forms. This product is also available for marine diesel operation.

-

This product features high reliability, low requirement for maintenance and simplicity of the few required connections and interfaces to ensure safe ignition of different gaseous, liquid and solid fuels. The Plasma Ignition System is usable for ignition of difficult to be ignited fuels like pulverized solid fuels (pre-dried lignite (PDL), hard coal and biomass) as well as gases, oils and special fuels. Additionally the ignition in low-oxygen or oxygen-free atmospheres is possible.

-

The Pony® Sample Conditioning System (PSCS®) is ideal for sampling wet or dry natural gas when a compact solution mounted directly to the sampling probe is preferred. The PSCS contains a self-limiting block heater, Watlow® PID temperature controller, system temperature limiter, and a single or multistage pressure regulator, all mounted inside a Pony® Heated Probe Enclosure. The close coupled system reduces the opportunity for richer gases to condense within sample tubing and protects analyzers from damage by solids or liquids while delivering a representative sample

-

The design of the Optograf process analyzer incorporates customer requirements for serviceability and hazard-area certification, provides a compact footprint, and minimizes utilities consumption. The high optical efficiency of the Optograf process Raman analyzer makes it ideal for measurement of gas-phase samples.

-

Wafer-type non-return (check) valves with spring, for installation in any position. Ideal for liquids, gases, and vapor applications. GESTRA's RK (wafer-type) non-return valves are for sandwiching between flanges. The valve has a spring to allow installation in any position. The valve self-centering body uses patented centering cams for RK 86/ RK 86A which make installation easier and faster – reducing costs. Our RK non-return valves are ideal for liquids, gases, and vapor applications.

-

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise probes can be inserted and retracted within a pressurized system for applications that need continual or instant corrosion monitoring. An electrical resistance (ER) probe measures both electrochemical and mechanical corrosion and is suited to corrosive environments with either poor or non-continuous electrolytes, such as vapors, gases, soils, wet hydrocarbons and nonaqueous liquids.

-

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.