Ensure your steam and water analysis system is to properly conditioned. From pressure, temperature and/or flow rate, your SWAS requires precise calibration from top to bottom for a truly representative sample. Select sample coolers, heat exchangers, thermal protection valves and much more based on your process environment.

-

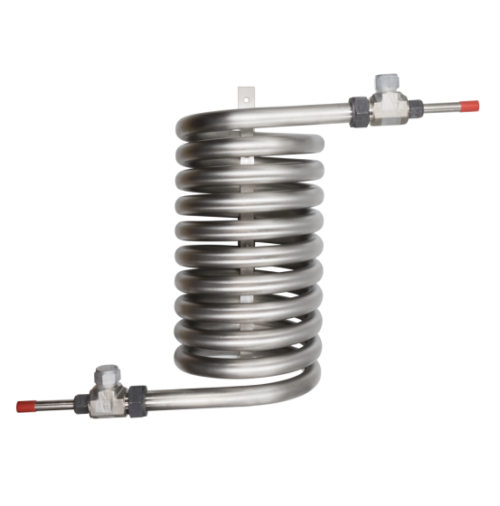

Sentry DTC (dual tube coil) tube-in-tube heat exchangers are spirally wound, full counter flow heat exchangers well suited for a variety of applications where low flow rates of high temperature and/or high pressure fluids need cooling or heating. The sturdy tube-within-a-tube concept uses heavy duty terminal fittings to provide for a plain tube end interface for the inner tube, and a compression connection for the outer tube.

-

The Sentry high-temperature shut-off valve is designed for use with sampling systems to shut off flow when the sample temperature becomes too hot. The valve is suitable for grab sample or instrument applications that could experience a loss of coolant or surges in sample flow rates, which would cause the sample temperture to rise suddenly.

-

The Sentry TSV is a self-contained, mechanical device that protects operators, analyzers and sampling components from high temperature liquids. It is an economical and reliable mechanical replacement for a solenoid shutoff valve and temperature controller, requiring no external source of electricity, air or hydraulics.

-

The Sentry W7950 sparger assembly is used to prepare a sample for taking a degassed cation conductivity measurement.

-

Out of stockSentry single line sample panels are pre-piped assemblies used to simplify the conditioning of steam, water or non-hazardous process samples. With the addition of cooling water, safe and representative samples can be obtained from individual sampling sites that are remotely located throughout the plant or from a small number of samples in a central location.

-

The Sentry W9000 Series sample coolers are designed for small volume hot water samples. The efficient counterflow design provides cooling for samples up to 750°F (399°C) and 3500 psig (241.3 barg), and the simplicity provides maximum cooling at minimal cost. With a compact design, simple installation and high quality materials, the W9000 Series sample coolers are the best low capacity option for small volume hot water samplers of water or other liquids.

-

The Sentry TRW sample cooler cools a sample from a process stream. It may seem simple, but it is a uniquely designed small tube in a shell heat exchanger. The sample to be cooled flows through the tube side of the cooler, and the cooling fluid, usually water, flows through the shell side. The cooled sample then is taken to a laboratory for analysis or piped to in-line process instrumentation for continuous monitoring of properties such as conductivity, pH or other chemical constituents