Heat and process fluid control

GESTRA is a global leader in the design and production of valves and control systems for heat and process fluid control. The products include steam traps, swing checks, boiler safety desuperheaters and specialty applications. The products are used wherever steam is generated, distributed, or used.

Products

-

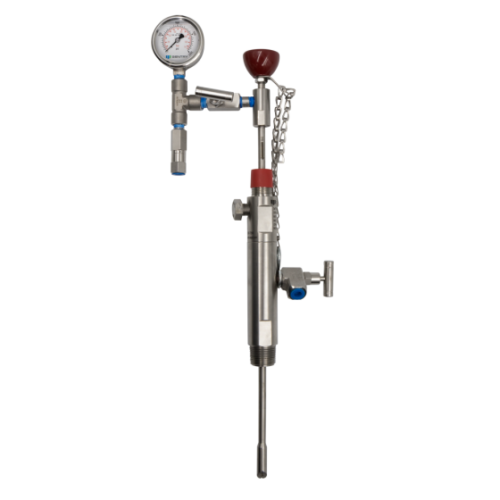

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise insertion tools are used to place and retrieve corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers into high-pressure applications without interruption of the system. With their sturdy but light construction—competitor tools can weigh five times more—these tools are operated easily by only one person and are designed to make insertion and retraction under pressure safe, easy and quick.

-

SBO gravity circulation check valves are installed downstream or upstream in heating and hot water installations to prevent gravity circulation. This ensures that the heating system works correctly, reliably, and at highest efficiency, reducing costs.

-

Self-aspirating gas fired igniters guarantee the reliable and safe ignition of main burners in furnaces and boilers if no air supply lines are available. SMITSVONK gas igniters can be equipped with one additional gas tube for increased heat release and flame stability.

-

Out of stockSentry single line sample panels are pre-piped assemblies used to simplify the conditioning of steam, water or non-hazardous process samples. With the addition of cooling water, safe and representative samples can be obtained from individual sampling sites that are remotely located throughout the plant or from a small number of samples in a central location.

-

Thermostatic steam traps are ideal for sterile and aseptic applications in the pharmaceuticals industry, including pure steam and ultrapure steam applications, clean-in-place, and steam-in-place processes.

-

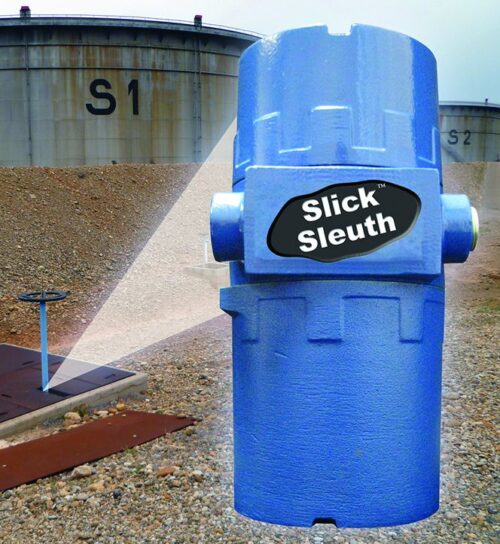

The Slick Sleuth® SS100 is designed for installation in above ground storage tank (AST) facilities, oil terminals, equipment rooms, or anywhere early oil leak and spill detection is needed. Detects a broad range of oil types on water and on dry ground—including spills, slicks, and sheen in tank dikes, sumps, oily water separators, mixing/dispatch points, loading racks, and storm water discharge points and outfalls. Oil detection sensors are used at single points or in a system array to continuously monitor for accidental leaks and spills.

-

The World’s most widely used sensor for detection of leaks & spills has been upgraded! The new SS100-LED offers greater range, the latest LED technology, and a field replaceable LED-source which comes with a 5 year warranty.

-

SpectraSensors SS2100 Gas Analyzers are exceptionally reliable for measuring trace gas components using Tunable Laser Diode (TDL) technology. The SS2100 is certified for CSA Class I Division 2.

-

The Slick Sleuth® SS300 and SS300EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS300 product series are used at refineries, power plants, heavy industries and terminals. These sensors are the optimal solution for detection of oil on water or on ground, concrete and solid surfaces.

-

The Slick Sleuth® SS320 and SS320EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS320 product series are used at marine terminals, particularly loading piers and wharves. These sensors are the optimal solution for detection of a wide range of oil-types, on water surfaces as well as dry ground.

-

Sentry Saf-T-Vise quills offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. The quills are versatile and can be configured either to inject chemicals into or take a sample from within a pressurized process such as a pipeline.

-

Sentry Saf-T-Vise insertion tools are used to place and retrieve corrosion coupon holders, injection & sample quills, or chemical injection nozzles & atomizers into high-pressure applications without interruption of the system. With their sturdy but light construction—competitor tools can weigh five times more—these tools are operated easily by only one person and are designed to make insertion and retraction under pressure safe, easy and quick.

-

SBO gravity circulation check valves are installed downstream or upstream in heating and hot water installations to prevent gravity circulation. This ensures that the heating system works correctly, reliably, and at highest efficiency, reducing costs.

-

Self-aspirating gas fired igniters guarantee the reliable and safe ignition of main burners in furnaces and boilers if no air supply lines are available. SMITSVONK gas igniters can be equipped with one additional gas tube for increased heat release and flame stability.

-

Out of stockSentry single line sample panels are pre-piped assemblies used to simplify the conditioning of steam, water or non-hazardous process samples. With the addition of cooling water, safe and representative samples can be obtained from individual sampling sites that are remotely located throughout the plant or from a small number of samples in a central location.

-

Thermostatic steam traps are ideal for sterile and aseptic applications in the pharmaceuticals industry, including pure steam and ultrapure steam applications, clean-in-place, and steam-in-place processes.

-

The Slick Sleuth® SS100 is designed for installation in above ground storage tank (AST) facilities, oil terminals, equipment rooms, or anywhere early oil leak and spill detection is needed. Detects a broad range of oil types on water and on dry ground—including spills, slicks, and sheen in tank dikes, sumps, oily water separators, mixing/dispatch points, loading racks, and storm water discharge points and outfalls. Oil detection sensors are used at single points or in a system array to continuously monitor for accidental leaks and spills.

-

The World’s most widely used sensor for detection of leaks & spills has been upgraded! The new SS100-LED offers greater range, the latest LED technology, and a field replaceable LED-source which comes with a 5 year warranty.

-

SpectraSensors SS2100 Gas Analyzers are exceptionally reliable for measuring trace gas components using Tunable Laser Diode (TDL) technology. The SS2100 is certified for CSA Class I Division 2.

-

The Slick Sleuth® SS300 and SS300EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS300 product series are used at refineries, power plants, heavy industries and terminals. These sensors are the optimal solution for detection of oil on water or on ground, concrete and solid surfaces.

-

The Slick Sleuth® SS320 and SS320EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS320 product series are used at marine terminals, particularly loading piers and wharves. These sensors are the optimal solution for detection of a wide range of oil-types, on water surfaces as well as dry ground.