Steam-Assisted Gravity Drainage

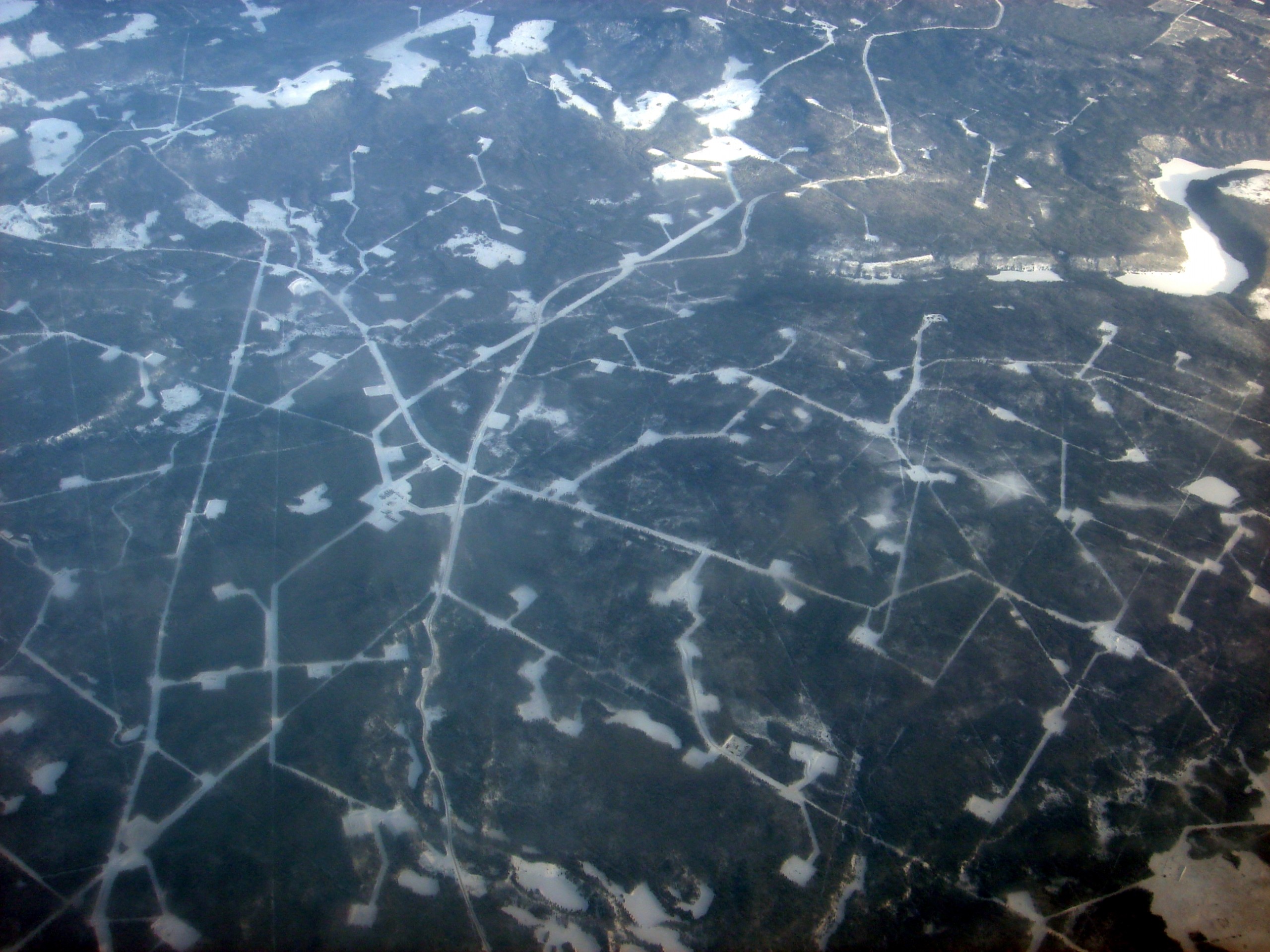

Steam-assisted gravity drainage (SAGD) was first developed to recover bitumen from the Alberta’s Canadian oil sands. Bitumen is an especially heavy, tar-like hydrocarbon known for its adhesive qualities. The principal idea behind SAGD is that two parallel horizontal wells are drilled through a reservoir, one above the other. The top well is used for injecting hot steam into the oil sands. The heat causes the heavy oil to thin and separate from the sand, and gravity drains the oil into the lower well, where it can be pumped to the surface. The top well, or steam chamber, can expand over time and eventually drain over a large area. This steam injection technique can improve heavy oil recovery by 50 to 60 percent more than other processes.

Once the oil and liquid steam condensate are pumped to the surface, they are separated, and the water can be recirculated for conservation and process efficiency. Approximately 90 percent of the steam can be recovered, according to the government of Alberta. Free oil, defined as large droplets, is removed with gravity separation or oil removal filters (ORF). The remaining oil is considered water soluble organics (WSOs).

Before the recovered water can be re-injected as steam, it must be treated and analyzed for oil content. SAGD boilers can tolerate some WSOs, but fouling of the boilers will occur if the free oil is not reduced to less than 1 ppm.

Turner Designs Hydrocarbon Instruments (TDHI) uses UV fluorescence to make accurate measurements of free oil in SAGD operations. Fluorescence measurement is capable and well suited to monitor most boiler feed waters for low concentrations of hydrocarbons. Although a continuous online measurement of oil in the SAGD water would be ideal, it is not possible at this time because of the water chemistry’s unique nature. The TD-550 Oil in Water Analyzer is designed for grab sample measurements in the SAGD production fields. Measurement interference from high WSO concentrations can be avoided through the toluene extraction method. Toluene has proven to be the most efficient solvent for extracting bitumen. These grab sample measurements provide an indication of process upsets and help the plant operators improve process control.

This article first appeared in News and Events, oilinwatermonitors.com.