The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

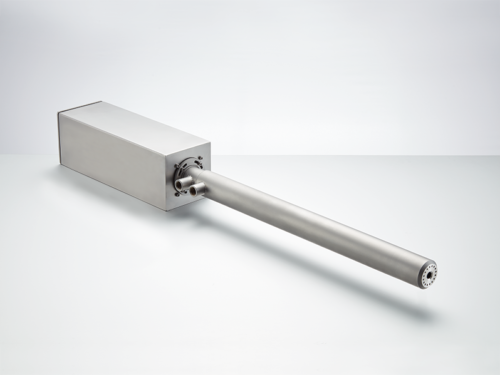

D-LL 7XX Fibre Optic System

Description

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

The fibre optic systems D-LL 701 and D-LL 702 have to be used in combination with the flame sensor D-LE 701. Fibre optic systems D-LL 703 and D-LL 704 are suitable for devices of type D-LE 703, D-LX 710 and D-LX 721.

The fibre optic systems D-LL 703 and D-LL 704 can be installed directly in the hot zones of the burner. The radiation of the flame is transferred outside by a temperature resistant fibre glass bundle and directed to the flame monitor.

Overview

Possible applications are:

- Flame monitoring of tilting burners

Flexible fibre optic systems allow tilting of the viewing direction together with the burner. - Flame monitoring without direct view

If there is no option to get a direct view of the flame from the installation position the line of sight can be bypassed around disturbing objects by using a flexible fibre optic system. - Flame monitoring for limited fields of view

On long, narrow burners the opening at the sighting tube often limits the viewing angle. Normally this does not constrain the recognition of a flame. But especially if there are several burners facing each other the discrimination of the flames can be difficult. Installing a flexible fibre optic system at each single burner increases the viewing angle for the dedicated burner and improves the selective flame monitoring. - Flame monitoring at high ambient temperatures

Recommended if high temperatures exist at the installation position.

If the ambient temperatures at the installation position are higher than specified for the flame monitor the usage of a fibre optic system allows the installation of the flame monitor in a different position with lower temperatures.

Applications

- Tilting burner (flexible system)

- Burners with difficult installation conditions for conventional flame sensors or on those whose environmental temperature near the sighting tube is too high

- Power stations

- Chemical industry

- Refineries

- Cement plants

- Waste incinerators

- Steam generators

- Heating plants

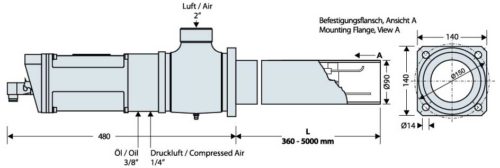

Technical Data

| Spectral ranges | UV, IR |

| Viewing angle | 6° |

| Perm. ambient temperature | -40…+350°C (optical system) |

| Purge air connection | G ½“ |

| Intermediate pipe material | 1.4301 |

| Weight | approx. 1.6 kg + 1 kg/m |

| Spectral ranges | UV, IR |

| Viewing angle | 6° |

| Perm. ambient temperature | -40…+350°C (optical system) |

| Purge air connection | G ½“ |

| Intermediate pipe material | 1.4301 |

| Weight | approx. 1.6 kg + 1 kg/m |

| Spectral ranges | UV, IR |

| Viewing angle | 6° |

| Perm. ambient temperature | -40…+350°C (optical system) |

| Purge air connection | G ½“ |

| Cooling air connection | G ½“ |

| Intermediate pipe material | 1.4301 |

| Weight | approx. 3 kg + 1 kg/m |

| Spectral ranges | UV, IR |

| Viewing angle | 6° |

| Perm. ambient temperature | -40…+350°C (optical system) |

| Purge air connection | G ½“ |

| Cooling air connection | G ½“ |

| Intermediate pipe material | 1.4301 |

| Weight | approx. 2 kg + 1 kg/m |

Resources

GENERAL INFORMATION

Product overview combustion technology / DE (4 MB)

Product overview combustion technology / EN (4 MB)

PRODUCT INFORMATION

Product brochure D-LL 7xx / DE (132 KB)

Product brochure D-LL 7xx / EN (133 KB)

FOR YOUR ENQUIRY

Questionnaire flame monitors / DE (275 KB)

Questionnaire flame monitors / EN (273 KB)