-

The World’s most widely used sensor for detection of leaks & spills has been upgraded! The new SS100-LED offers greater range, the latest LED technology, and a field replaceable LED-source which comes with a 5 year warranty.

-

The Slick Sleuth® SS320 and SS320EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS320 product series are used at marine terminals, particularly loading piers and wharves. These sensors are the optimal solution for detection of a wide range of oil-types, on water surfaces as well as dry ground.

-

The Slick Sleuth® SS300 and SS300EXd are designed for deployment in rugged settings such as offshore, coasts, harbors, inland waterways, industrial facility drainage and outfalls, or anywhere risk of an oil spill is a concern. The SS300 product series are used at refineries, power plants, heavy industries and terminals. These sensors are the optimal solution for detection of oil on water or on ground, concrete and solid surfaces.

-

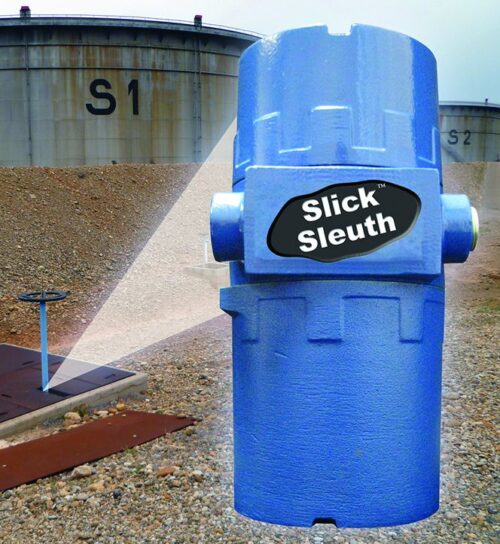

The Slick Sleuth® SS100 is designed for installation in above ground storage tank (AST) facilities, oil terminals, equipment rooms, or anywhere early oil leak and spill detection is needed. Detects a broad range of oil types on water and on dry ground—including spills, slicks, and sheen in tank dikes, sumps, oily water separators, mixing/dispatch points, loading racks, and storm water discharge points and outfalls. Oil detection sensors are used at single points or in a system array to continuously monitor for accidental leaks and spills.

-

SpectraSensors SS2100 Gas Analyzers are exceptionally reliable for measuring trace gas components using Tunable Laser Diode (TDL) technology. The SS2100 is certified for CSA Class I Division 2.

-

The J22 Gas Analyzer uses patented tunable diode laser absorption spectroscopy (TDLAS) technology to provide accurate measurement of H2O in natural gas. Featuring the reliable diagnostic capabilities of Heartbeat Technology, the J22 analyzer determines the concentration of a gas without coming into physical contact with streams. It allows pipeline operators and suppliers to meet quality specifications, prevent pipeline corrosion, and stop hydrate formation to ensure safety and asset integrity.

-

The design of the Optograf process analyzer incorporates customer requirements for serviceability and hazard-area certification, provides a compact footprint, and minimizes utilities consumption. The high optical efficiency of the Optograf process Raman analyzer makes it ideal for measurement of gas-phase samples.