Heat and process fluid control

GESTRA is a global leader in the design and production of valves and control systems for heat and process fluid control. The products include steam traps, swing checks, boiler safety desuperheaters and specialty applications. The products are used wherever steam is generated, distributed, or used.

Products

-

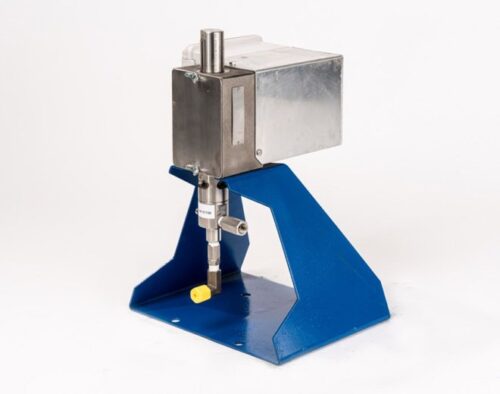

An economical option where low rates and pressures are needed for the application. Available in single head only. Stainless steel wetted parts are used to ensure long lasting dependability

-

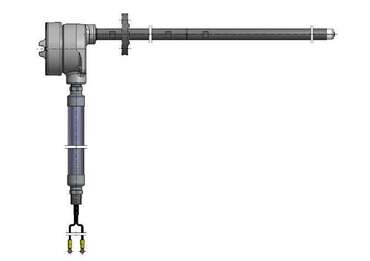

Ignition lance with high voltage cable, guided in a metal hose, for hazardous areas according NEC 500. This design boasts flexible customization for specific installation conditions as well as easily replaceable ignition tips which are specialized for ignition of HFO or at high pressure.

-

InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.

-

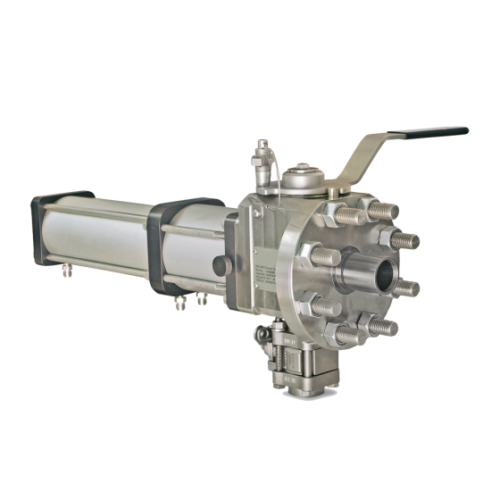

The Sentry ISOLOK SAL-DBB automatic point sampler collects representative liquid and slurry samples in harsh operating conditions, such as oil sand mining. Safety, reliability, convenience and ease of service are all designed into this sampler, which features patented double block and bleed technology.

-

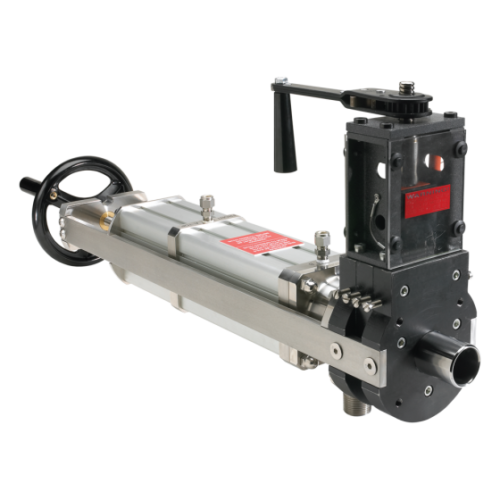

The Sentry ISOLOK SAL-Q automatic point sampler is a heavy-duty, isolatable sampler using ISOLOK proven technology and suitable for oil sands and other mining applications. The Sentry ISOLOK SAL-Q sampler employs the industry-proven Delta double block and bleed, ANSI-rated knife gate valve to isolate the sampler from the process line when the sampler needs servicing.

-

The J22 Gas Analyzer uses patented tunable diode laser absorption spectroscopy (TDLAS) technology to provide accurate measurement of H2O in natural gas. Featuring the reliable diagnostic capabilities of Heartbeat Technology, the J22 analyzer determines the concentration of a gas without coming into physical contact with streams. It allows pipeline operators and suppliers to meet quality specifications, prevent pipeline corrosion, and stop hydrate formation to ensure safety and asset integrity.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

The Packing Leak Detector (PLD) helps reduce leak rates to near zero. Methane leaks from compressor packing glands are common and result in lost revenue and can lead to environmental penalties. The PLD provides mechanical or digital notification of a leak allowing for early intervention and remedy.

-

The MAX100-BTU provides a rapid, high precision measurement of heating value and gas composition for optimal combustion control and environmental compliance.The MAX100-BTU uses cutting-edge quadrupole mass spectrometer technology to deliver a continuous online analysis of fuel gas and vent streams containing hydrocarbons, H2, CO, CO2, H2O, H2S and other gases. It has the speed necessary to analyze the total composition of the sample and report the Heating Value in seconds.

-

The MAX300-AIR is an industrial gas analyzer optimized for environmental and ambient air monitoring and regulatory compliance. Quadrupole mass spectrometry is extremely sensitive and very fast, allowing for the rapid detection and quantitation of a wide variety of toxic industrial contaminants. The speed of the MAX300-AIR allows one analyzer to measure unlimited compounds and be automated to monitor 160+ sample points, spread throughout the manufacturing site.

-

Fast, Accurate, Efficient Mass Spectrometry is a powerful tool for bioreactor monitoring. Changes to the composition of bioreactor or fermentor off-gas provide crucial insight into cellular health and production efficiency. This makes the fast, accurate analysis of CO2, O2, N2, Ar, H2O and other compounds essential for real-time process control. The MAX300-BIO uses cutting edge quadrupole mass spectrometer technology to quantify bioreactor gases from multiple reactors within the facility and reports the data to the control system in real-time.

-

An economical option where low rates and pressures are needed for the application. Available in single head only. Stainless steel wetted parts are used to ensure long lasting dependability

-

Ignition lance with high voltage cable, guided in a metal hose, for hazardous areas according NEC 500. This design boasts flexible customization for specific installation conditions as well as easily replaceable ignition tips which are specialized for ignition of HFO or at high pressure.

-

InSight is designed for high pressure combustible gas systems. It will be able to safely access systems via existing tapping points and become a versatile tool to perform a number of tasks that currently require a plant shutdown. InSight will have the ability to investigate the internal condition of piping and pressure vessels Additional tools will enable operators to troubleshoot operations problems such as foaming or fouling.

-

The Sentry ISOLOK SAL-DBB automatic point sampler collects representative liquid and slurry samples in harsh operating conditions, such as oil sand mining. Safety, reliability, convenience and ease of service are all designed into this sampler, which features patented double block and bleed technology.

-

The Sentry ISOLOK SAL-Q automatic point sampler is a heavy-duty, isolatable sampler using ISOLOK proven technology and suitable for oil sands and other mining applications. The Sentry ISOLOK SAL-Q sampler employs the industry-proven Delta double block and bleed, ANSI-rated knife gate valve to isolate the sampler from the process line when the sampler needs servicing.

-

The J22 Gas Analyzer uses patented tunable diode laser absorption spectroscopy (TDLAS) technology to provide accurate measurement of H2O in natural gas. Featuring the reliable diagnostic capabilities of Heartbeat Technology, the J22 analyzer determines the concentration of a gas without coming into physical contact with streams. It allows pipeline operators and suppliers to meet quality specifications, prevent pipeline corrosion, and stop hydrate formation to ensure safety and asset integrity.

-

LineVu reveals contamination in high pressure natural gas systems that until now has been un-detected. Despite commercial and legal contracts requiring that no liquids or solids should enter a gas network, it is common to find that liquid contamination is the cause of damage to power stations and other plant all over the world.

-

The Packing Leak Detector (PLD) helps reduce leak rates to near zero. Methane leaks from compressor packing glands are common and result in lost revenue and can lead to environmental penalties. The PLD provides mechanical or digital notification of a leak allowing for early intervention and remedy.

-

The MAX100-BTU provides a rapid, high precision measurement of heating value and gas composition for optimal combustion control and environmental compliance.The MAX100-BTU uses cutting-edge quadrupole mass spectrometer technology to deliver a continuous online analysis of fuel gas and vent streams containing hydrocarbons, H2, CO, CO2, H2O, H2S and other gases. It has the speed necessary to analyze the total composition of the sample and report the Heating Value in seconds.

-

The MAX300-AIR is an industrial gas analyzer optimized for environmental and ambient air monitoring and regulatory compliance. Quadrupole mass spectrometry is extremely sensitive and very fast, allowing for the rapid detection and quantitation of a wide variety of toxic industrial contaminants. The speed of the MAX300-AIR allows one analyzer to measure unlimited compounds and be automated to monitor 160+ sample points, spread throughout the manufacturing site.

-

Fast, Accurate, Efficient Mass Spectrometry is a powerful tool for bioreactor monitoring. Changes to the composition of bioreactor or fermentor off-gas provide crucial insight into cellular health and production efficiency. This makes the fast, accurate analysis of CO2, O2, N2, Ar, H2O and other compounds essential for real-time process control. The MAX300-BIO uses cutting edge quadrupole mass spectrometer technology to quantify bioreactor gases from multiple reactors within the facility and reports the data to the control system in real-time.