Heat and process fluid control

GESTRA is a global leader in the design and production of valves and control systems for heat and process fluid control. The products include steam traps, swing checks, boiler safety desuperheaters and specialty applications. The products are used wherever steam is generated, distributed, or used.

Products

-

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

-

Flame sensor (flame scanner) for the monitoring of gas, oil and coal flames, primarily in single burner view applications.

-

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

-

Self-monitoring and fail-safe compact flame monitor for the monitoring of gas, oil and coal flames with integrated UV, VIS or IR flame sensor, primarily in single burner view applications.

-

Compact and cost effective transmittance dust and opacity measuring device for monitoring medium to high dust concentrations in dry flue and process gas.

-

The Sentry W7950 sparger assembly is used to prepare a sample for taking a degassed cation conductivity measurement.

-

Compact thermodynamic steam traps are ideal for draining heating processes with small load fluctuations, including saturated and superheated steam systems, steam tracing, and air heaters.

-

Sentry DPA Series offers easy-to-use drip pot assemblies to collect samples within a pipeline or other pressurized system for the purpose of examining and measuring corrosion products and other contaminants, without interruption to the system. Drip pot assemblies collect the samples for analysis using a container with an interior reservoir for receiving a liquid sample, and a valve assembly coupled to the drip pot.

-

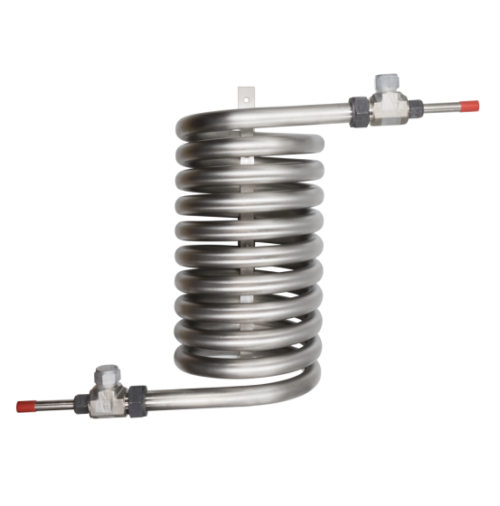

Sentry DTC (dual tube coil) tube-in-tube heat exchangers are spirally wound, full counter flow heat exchangers well suited for a variety of applications where low flow rates of high temperature and/or high pressure fluids need cooling or heating. The sturdy tube-within-a-tube concept uses heavy duty terminal fittings to provide for a plain tube end interface for the inner tube, and a compression connection for the outer tube.

-

Ambient air particulate monitor to detect TSP, PM10 or PM2.5 in ambient air for use in industrial or governmental ambient air monitoring networks.

-

A flame front generator is a system in which a gas/air mixture is introduced at ground level and flows up a one-inch line to the pilot burner. After filling this line with the mixture it is ignited by a spark. The resulting flame travels to the top of the flare where the pilot burner is ignited.

-

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions. Flame front ignition version of this product is also available

-

Flame sensor (flame scanner) for the monitoring of gas and oil flames, primarily in gas turbines or in particularly harsh environments.

-

Flame sensor (flame scanner) for the monitoring of gas, oil and coal flames, primarily in single burner view applications.

-

The installation of fibre optic systems is recommended if it is not possible to place the flame monitor at an optimal position in order to guarantee best and permanent flame monitoring. A fibre optic system is also useful if the conditions of the environment are harsh to electronic devices.

-

Self-monitoring and fail-safe compact flame monitor for the monitoring of gas, oil and coal flames with integrated UV, VIS or IR flame sensor, primarily in single burner view applications.

-

Compact and cost effective transmittance dust and opacity measuring device for monitoring medium to high dust concentrations in dry flue and process gas.

-

The Sentry W7950 sparger assembly is used to prepare a sample for taking a degassed cation conductivity measurement.

-

Compact thermodynamic steam traps are ideal for draining heating processes with small load fluctuations, including saturated and superheated steam systems, steam tracing, and air heaters.

-

Sentry DPA Series offers easy-to-use drip pot assemblies to collect samples within a pipeline or other pressurized system for the purpose of examining and measuring corrosion products and other contaminants, without interruption to the system. Drip pot assemblies collect the samples for analysis using a container with an interior reservoir for receiving a liquid sample, and a valve assembly coupled to the drip pot.

-

Sentry DTC (dual tube coil) tube-in-tube heat exchangers are spirally wound, full counter flow heat exchangers well suited for a variety of applications where low flow rates of high temperature and/or high pressure fluids need cooling or heating. The sturdy tube-within-a-tube concept uses heavy duty terminal fittings to provide for a plain tube end interface for the inner tube, and a compression connection for the outer tube.

-

Ambient air particulate monitor to detect TSP, PM10 or PM2.5 in ambient air for use in industrial or governmental ambient air monitoring networks.

-

A flame front generator is a system in which a gas/air mixture is introduced at ground level and flows up a one-inch line to the pilot burner. After filling this line with the mixture it is ignited by a spark. The resulting flame travels to the top of the flare where the pilot burner is ignited.

-

Ignition of waste gas from pipe flares, air and steam assisted flares and ground flares. For most flare systems the pilot burner can not be accessed for service. Maintenance or replacement is not possible while the flare is in operation. To safeguard operation, Smitsvonk’s pilots provide reliable ignition and stable burning even under the most difficult climate conditions. Flame front ignition version of this product is also available