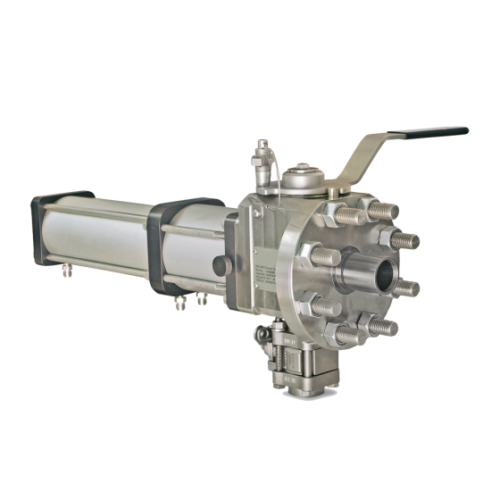

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

Saf-T-Vise Corrosion Coupon Holders

Description

Description

SENTRY SAF-T-VISE COUPON HOLDERS – THE SAFEST CHOICE UNDER PRESSURE

Metal corrosion is inevitable, and has the potential to cause catastrophic pipeline and assets failure, damaging the environment and communities, injuring field operators, and causing costly downtime and waste in productivity. However, corrosion is easy to measure.

Sentry Saf-T-Vise coupon holders offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. These coupon holders work with a variety of corrosion coupons, including rod (cylinder), flat (strip) single hole, flat (strip) dual hole, and disk, to measure the rate of corrosion within a pressurized process such as a pipeline.

Benefits

Saf-T-Vise coupon holders are hand insertable (low pressure) or mechanically insertable (high pressure) into your pressurized system. With a wide range of pressure ratings available, Saf-T-Vise coupon holders are the optimal choice for corrosion monitoring and protecting most pressurized applications. They can be mounted in any orientation with extended insertion lengths of up to 20 feet for hard-to-access application situations. Saf-T-Vise STV-T Series insertion tools are used for mechanically inserting the corrosion coupon rods.

Models

| Model | insertion pressure (MOP) | pressure rating (MAP) | temperature rating (seals) | materials |

|---|---|---|---|---|

| STV-LP1-C | 750 psi at 100°F (52 bar at 38°C) | 2000 psi at 100°F (207 bar at 38°C) | PTFE: 450°F (232°C) | 316/316L SS |

| STV-LP2-C | 1/4 in: 1000 psi at 100°F (69 bar at 38°C) 3/8 in: 750 psi at 100°F (52 bar at 38°C) 1/2 in: 420 psi at 100°F (29 bar at 38°C) |

4000 psi at 100°F (275 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP1-C | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP2-C | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316L SS |

| STV-XH1-C | 10,000 psi at 100°F (689 bar at 38°C) | 10,000 psi at 100°F (689 bar at 38°C) | PTFE: 450°F (232°C) | 410 SS; other alloys available |

*Graphoil seals are available for higher temperature applications; contact factory for details

MAP: Maximum Allowable Pressure

MOP: Maximum Operating Pressure

Features

- Process pressure bleeder valve

- Integrated safety cap or chain, depending on model

- Designed and manufactured in accordance with ASME B31.3

- Canadian Registration Number available for most models

- Process wetted components comply with NACE MR0175/2009 and are suitable for service in hydrogen sulfide (H2S) environments

| Temperature Rating | PTFE: 450°F (232°C) |

|---|