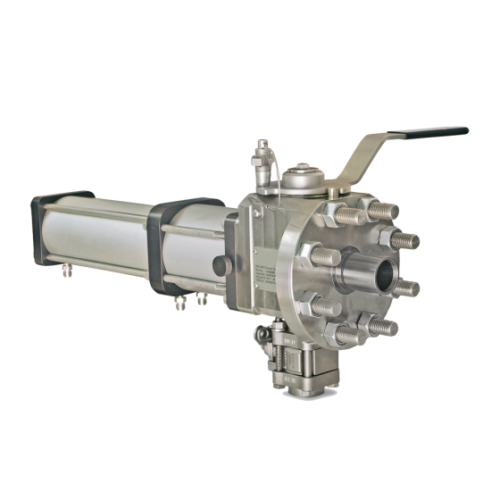

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

Saf-T-Vise Chemical Injection Atomizers

Description

Description

SENTRY SAF-T-VISE ATOMIZERS – THE SAFEST CHOICE UNDER PRESSURE

Sentry Saf-T-Vise atomizers offer ease of use and custom configuration for maximum versatility. The Saf-T-Vise patented locking collet is simple to use and enhances operator safety by safely securing the shaft within the process stream in both low and extremely high pressure conditions. A variety of atomizer configurations are available to provide the best delivery of the required chemicals to prevent or mitigate corrosion within a pressurized process such as a pipeline.

Benefits

Models

| Model | insertion pressure (MOP) | pressure rating (MAP) | temperature rating (seals) | materials |

|---|---|---|---|---|

| STV-LP1-A | 750 psi at 100°F (52 bar at 38°C) | 2000 psi at 100°F (207 bar at 38°C) | PTFE: 450°F (232°C) | 316/316L SS |

| STV-LP2-A | 3/8 in: 750 psi at 100°F (52 bar at 38°C) 1/2 in: 420 psi at 100°F (29 bar at 38°C) |

4000 psi at 100°F (275 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP1-A | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS; other alloys available |

| STV-HP2-A | 5000 psi at 100°F (344 bar at 38°C) | 5000 psi at 100°F (344 bar at 38°C) | PTFE: 450°F (232°C) graphoil: * |

316/316L SS |

*Graphoil seals are available for higher temperature applications; contact factory for details

MAP: Maximum Allowable Pressure

MOP: Maximum Operating Pressure

Features

- Process pressure bleeder valve

- Patented locking collet safely secures the shaft within the process stream until released by the operator

- Integrated safety cap or chain, depending on model

- Multiple nozzle choices: 1/8 inch male or female NPT connections standard; other connection sizes and types available

- Designed and manufactured in accordance with ASME B31.3

- Canadian Registration Number available for most models

- Process wetted components comply with NACE MR0175/2009 and are suitable for service in hydrogen sulfide (H2S) environments

| Wetted Materials | 316/316L SS |

|---|---|

| Temperature Rating | PTFE: 450°F (232°C) |